Specialize in Compression molds

Specialize in Compression molds

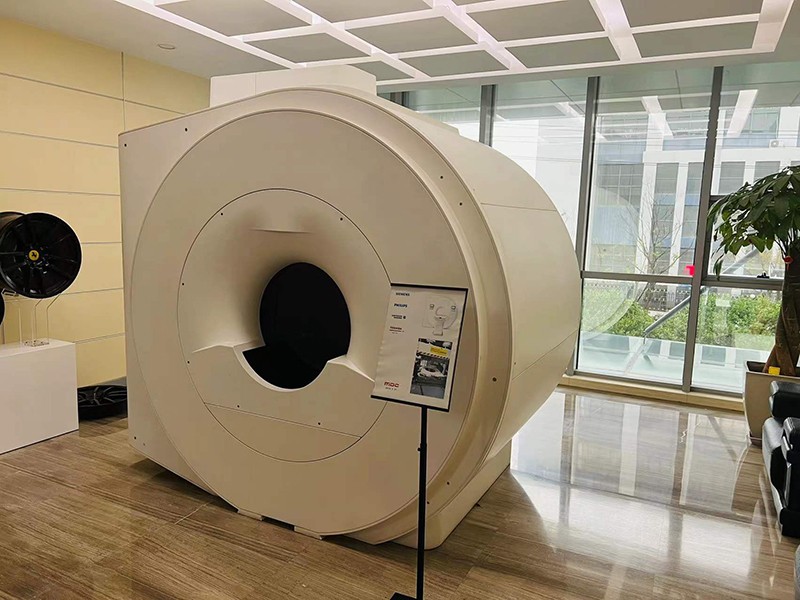

Mri is not strange to most people, in the hospital, we can often see it, for ordinary people, it is huge, is to check the health of each part of the human body is a kind of instrument.

Medical devices such as MRI and CT scanners have either a radiation effect or a super strong magnetic field effect on the surrounding objects. For these reasons, the metal parts cannot be used.

So what's the material that makes the big shell of an MRI, which could be used for medical purposes? Can realize the shell hardness is strong at the same time take into account light?

Thermoplastic materials are widely used in MRI and CT equipment. However, thermoplastic materials also have some problems such as short service life and easy weathering. Because of its high strength, long service life and high cost performance, SMC medical molds have been widely used in the manufacture of MRI and CT scanner shells.

Yes, we are going to mention our SMC moulding today, I believe that through the previous understanding, we have a deep understanding of the SMC moulding itself has the characteristics! SMC moulding products generally have the advantages of rigidity, deformation resistance, large temperature range, lightweight and high strength. Therefore, NMR also began to widely used "SMC" mold, by everyone's welcome and recognition.

MDC Mould has cooperated with international manufacturers in aerospace, automobile, truck, high-speed rail, medical and other fields, and obtained their recognition and authorization licenses. Provide solutions to customers in composite material application, and provide feasibility analysis and technical support to customers in new product development. Today we talk about nuclear magnetic resonance, Dacheng mold is very experienced in the production of this aspect, welcome to contact!

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China