Specialize in Compression molds

Specialize in Compression molds

The use of prepregs has gained popularity over the last few years and has become an effective alternative for the high-volume production of structural parts. With this technology, it is possible to produce high-performance structural parts (up to 70% FVF) with cycle times as low as 2 minutes.

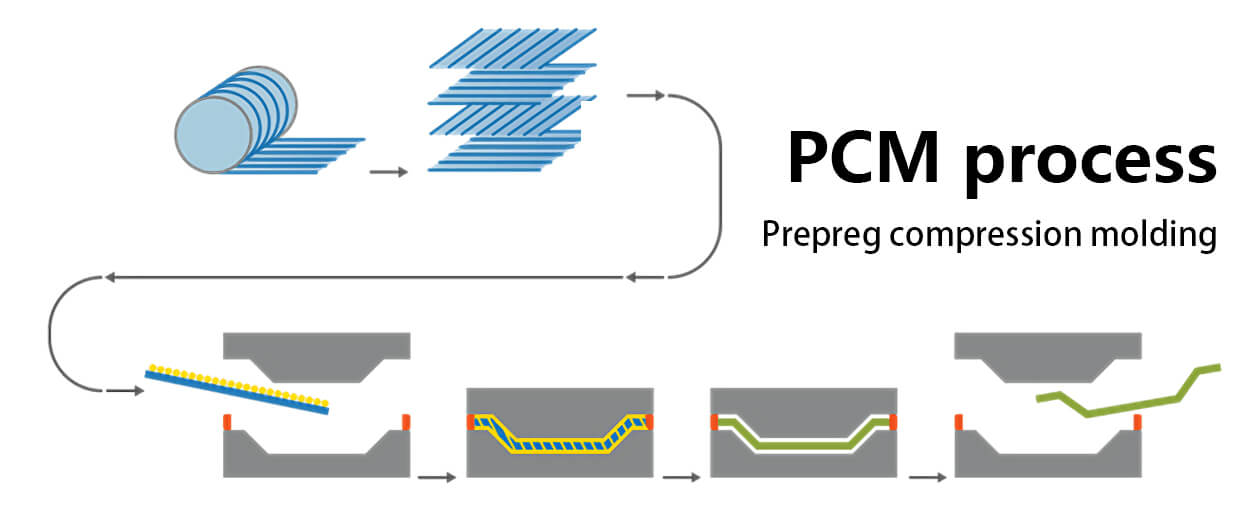

PCM (Prepreg Compression Molding) is a process for manufacturing resin-impregnated fiber-reinforced parts based on the production of complex geometries with high strength-to-weight ratios in a compression process with lower processing pressures compared to the injection process.

The technology involves placing the prepreg on a PCM mold and then further molding it in a press (at low or medium pressure) in a heated mold. PCM technology can be applied to SMC molding or carbon fiber molding to produce automotive parts or aircraft components.

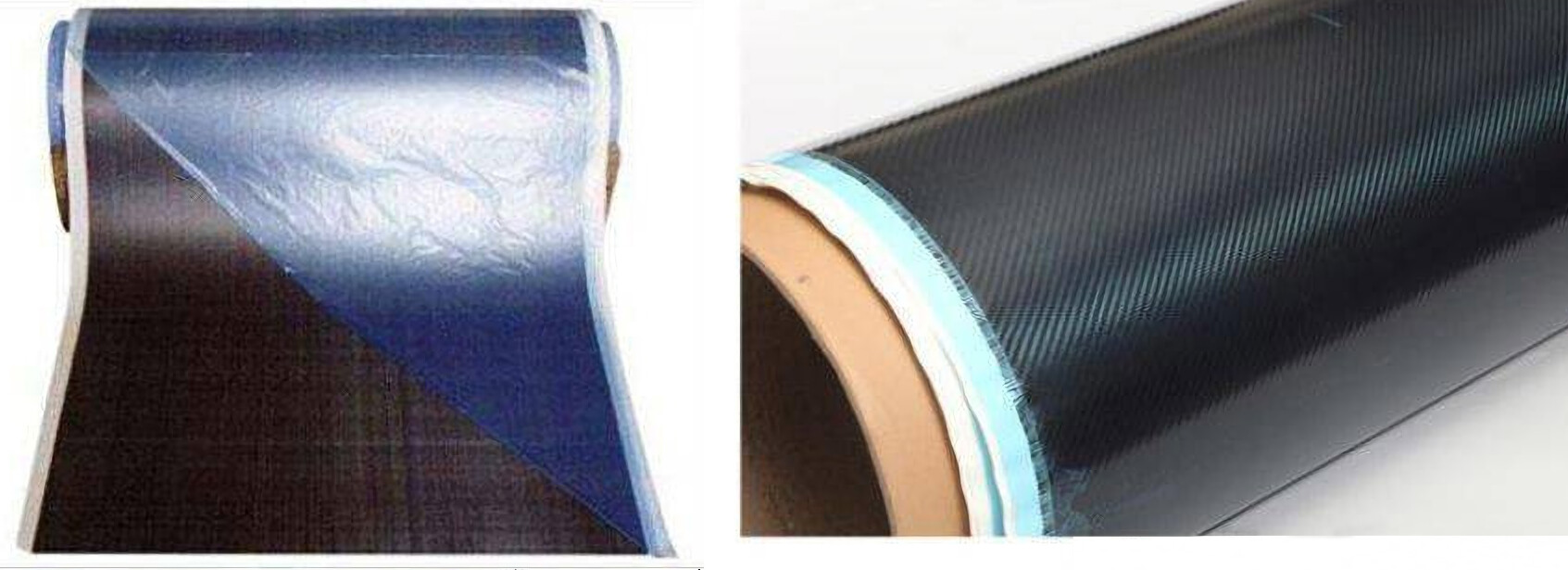

Prepreg is a pre-molded glass fiber imitation into a blank that matches the product's structure, shape, and size. This blank is then hot pressed into the product by adding a resin mixture during the molding process. It is compared with the mass molding plastic, using longer fibers (25mm, 38mm, and 50mm three lengths) and higher fiber content (20% a 40%), the mechanical properties of the product are better. Since the prepreg material basically does not flow during the PCM molding process, the prepreg material can only be pressed for products with greater depth and shape dimensions and less complex shapes. Prepregs are very strong, extremely light, and unstoppable in a growing number of industries. These composites of two or more materials develop new properties that the starting materials alone do not possess. Fiber-reinforced plastics, in particular, possess maximum strength and stiffness as well as exceptionally lightweight. In addition, there are other benefits, such as corrosion resistance and long service life. With the help of modern production processes, these high-quality materials can be optimized for various applications and tasks. The required PCM molds have been designed and manufactured by MDC for more than 20 years.

The methods of prepreg preparation can be divided according to the glass fiber delivery medium and the mode of operation. The preparation of prepregs is an important part of the PCM process, which is carried out with the help of performers. There are many performers, and there are two types of performers: air type and water type, depending on the carrier medium (or carrier) of the glass fiber. The air type is divided into closed type (pressure ventilation chamber type) and open type (open jet injection or fiber direct injection type).

| Component | Dosage / portion | Ratio within the press | Final composition within the molded product |

| Polyester resin (viscosity 3.5 Pa •s) | 68. 0 | 65% | 48.7% |

| Styrene monomer (to bring resin viscosity down to 0. 8 Pa •s) | 7 | ||

| Tert-butyl hydroperoxide initiator | 0.6 | ||

| Muches or calcium carbonate filler | 25. 0 | 16.3% | |

| Internal release agent | 0.1 | ||

| Colorant | 0.5~5.0 | ||

| Glass Fiber Reinforced Material | - | 35% | 35% |

MDC Mould manufacture and develop custom PCM mold and prepreg compression molding systems in a variety of sizes and configuration levels. All molding solutions are tailored to the customers needs. When we receive your order, professional sales staff will understand your project needs in detail. Based on part requirements, we will help you design and manufacture PCM molds.

In addition, our services include product design, custom prepreg customization, part post-processing steps, and more. And we will provide videos and images throughout the project cycle to report the progress of the project in time to reduce your worries. Remember, MDC is one of the professional PCM mold manufacturers in China. Get your own molds now at the cheapest price!

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China