Specialize in Compression molds

Specialize in Compression molds

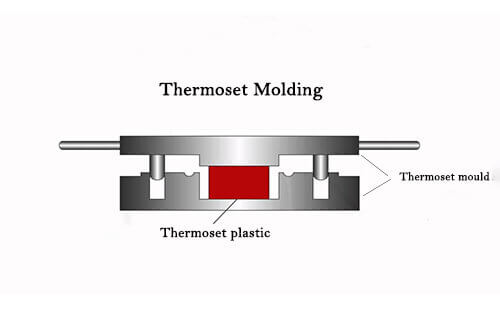

Thermoset molding is an irreversible molding process through which plastic forms of plastics are pressed into heated molds and form their final shape. Thermosetting materials are generally stronger than thermoforming materials and are also more suitable for high-temperature applications. This is because the catalyst added to the base compound causes chemical reactions at the molecular level to form a hard, irreversible final product. Thermoset plastics can not be remelted and can only be ground and recycled as fillers for different applications. Both injection molding and compression molding can be used for thermoset materials. Thermoset compression molding offers many advantages and provides a range of benefits. Common thermoset materials include polyester, silicone, melamine, polyurethane, epoxy, and urea-formaldehyde. The benefits of thermoset materials include their high strength and impact resistance, low shrinkage and excellent dimensional stability.

Thermoset molding is an irreversible molding process through which plastic forms of plastics are pressed into heated molds and form their final shape. Thermosetting materials are generally stronger than thermoforming materials and are also more suitable for high-temperature applications. This is because the catalyst added to the base compound causes chemical reactions at the molecular level to form a hard, irreversible final product. Thermoset plastics can not be remelted and can only be ground and recycled as fillers for different applications. Both injection molding and compression molding can be used for thermoset materials. Thermoset compression molding offers many advantages and provides a range of benefits. Common thermoset materials include polyester, silicone, melamine, polyurethane, epoxy, and urea-formaldehyde. The benefits of thermoset materials include their high strength and impact resistance, low shrinkage and excellent dimensional stability.

Thermoset molds are mainly used for forming thermoset plastic products, that is, processing and forming powdered thermoset plastics. Types include thermoset compression mold, thermoset transfer mold and thermoset injection mold. Among them, compression molding are the most used, and injection molding process are less. There is no gating system in the thermoset mold, and there is a cavity or feeding chamber as the space to accommodate the forming material, and the material is preheated. The forming pressure is directly applied to plastic parts by die, which is suitable for plastics with poor forming fluidity or various fillers. And the orientation of the plastic parts is less, the orientation degree is low, and the performance of each direction is more uniform.

Thermoset composites are the most common type of material used in compression mold. There are four main steps to the thermoset compression molding process:

Thermoset molds are capable of producing and manufacturing a wide variety of products. Thermoset molding has many applications in the electrical industry, including motor housings, control panels, etc. Thermoset molded parts have tighter tolerances and are used in the medical industry and automotive applications.

Metals are expensive and may require secondary processing. Thermoset plastic molding can integrate many parts, eliminating the cost of secondary processing of parts and paint. How can MDC Mould do this? MDC offers integrated manufacturing solutions involving thermoset tools and products. We help you convert existing metal parts to thermoset plastics to improve product performance while reducing manufacturing costs.

Your products may be applied in environments where they are exposed to oils, chemical fluids and rain vapors. MDC Mould is a well-known supplier and manufacturer of many product end markets.

Components are susceptible to degradation if they are subjected to high temperatures for long periods of time. Thermoset mold produce high heat resistant parts - resistance to heat distortion and dimensional stability to 50 degrees Celsius or more. MDC Mould is a leading manufacturer of thermoset parts with heat resistant components that remain stable despite high operating pressures and high durability.

As a custom thermoset mold supplier, MDC Mould provide thermoset molds manufacturing and thermoset molding services such as phenolic resins, BMC, DMC, SMC and epoxy resins. Large, multi-cavity, high-quality thermoset molds are one of our unique core competencies.

MDC have 500 to 4000 tons of thermoset molding machine that enable us to make various thermoset parts. MDC thermoset molding parts are used in various products that need to protect them from high temperature, corrosion, and electrical environment, as well as exposure to chemicals or fluids, to achieve lightweight requirements, and to reduce costs and save time for product assembly.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China