Specialize in Compression molds

Specialize in Compression molds

Composite materials are materials with new properties composed of two or more materials with different properties through physical or chemical methods. With the broadening of the application field of composite materials, the composite material forming process has been developed rapidly, the old forming process is being perfected day by day, and new forming methods are constantly emerging. Common processes include hand lay-up, injection molding, resin injection (RTM), compression molding (BMC, SMC), vacuum infusion molding, etc.

To make high-precision composite products, composite molds are the most important part of the entire production process. And the shape and appearance of the product need to be guaranteed by the mold. The composite material mould usually puts the composite material into the hot pressing mold, and then melts the composite material by heating the mold. There is an ejection mechanism inside the mold, which can eject the formed product and make it out of the mold. Common heating methods for composite material molds include: oil heating, electric heating, steam heating, etc.

Composite molds vary widely, depending on the industry and application, covering automotive, electrical, sanitary, building materials, aerospace and many other fields. Compared with metal molds, composite molds have many advantages, so what are the advantages of composite molds?

1. The specific strength and specific stiffness of the composite mould are relatively high.

2. The mechanical properties of the composite material muold can be designed, that is, the composite material component or composite material structure can meet the use requirements by selecting suitable raw materials and reasonable lay-up forms.

3. The composite mould has good fatigue resistance.

4. The vibration damping performance of the composite material mould is good.

5. Composite molds are usually resistant to high temperatures.

6. The safety of the composite material mould is good.

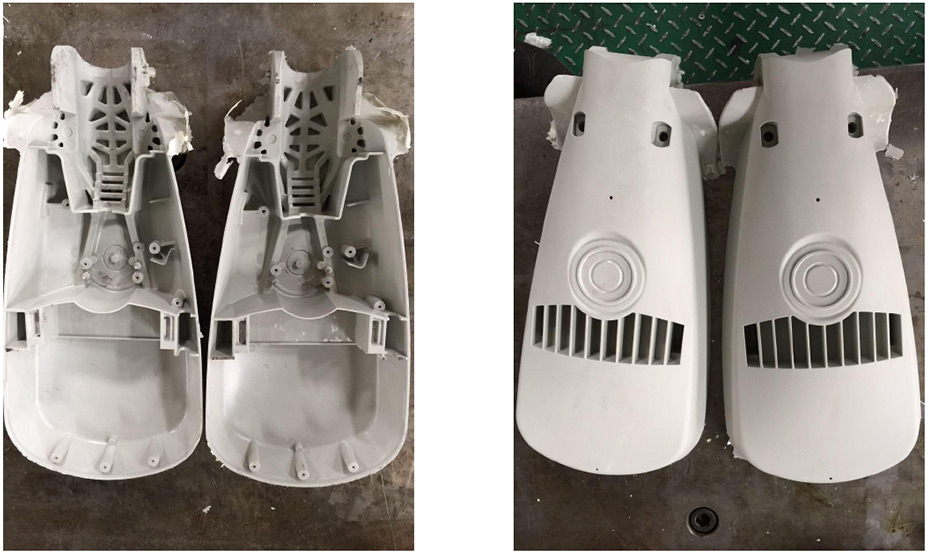

As a mature composite mould manufacturer in China, MDC manufactures various types of glass fiber composite molds (glass fiber reinforced plastic molds, such as SMC, BMC, GMT, LFT), carbon fiber composite molds, and LWRT composite molds.

The molds manufactured by MDC include: spoiler templates, fenders, bumpers, and front panel molds on trucks; hoods, doors, bottom guards, roofs, seat backs, and luggage molds on cars; electrical appliances Box and bathroom door basin mold and so on. The composite material molds we produce have been effectively optimized, with longer service life, lower manufacturing costs, and higher precision products.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China