Specialize in Compression molds

Specialize in Compression molds

SMC is a mixture of polymer resin, inert fillers (calcium carbonate, talc or wollastonite), fibre reinforcement, catalysts, pigments, stabilizers, release agents, and thickeners. The glass reinforcement is between 10% and 60%, and the fiber length is slightly longer than that of the bulk molding compounds (BMC). SMC production method assures full integration of fibres and resins. Manufacturing of SMC is a continuous in-line process. Generally: Sheet molding compound made of fibre impregnated with resin paste or chopped fibre mat covered with polyhexene film on both sides.

SMC is a mixture of polymer resin, inert fillers (calcium carbonate, talc or wollastonite), fibre reinforcement, catalysts, pigments, stabilizers, release agents, and thickeners. The glass reinforcement is between 10% and 60%, and the fiber length is slightly longer than that of the bulk molding compounds (BMC). SMC production method assures full integration of fibres and resins. Manufacturing of SMC is a continuous in-line process. Generally: Sheet molding compound made of fibre impregnated with resin paste or chopped fibre mat covered with polyhexene film on both sides.

SMC mould is high-strength, high hardness mould made of steel plates with polished surfaces to ensure the surface quality of the SMC moulded parts. The main feature of this mould is that it is made by using a compression process in order to compress the SMC material into the final product. SMC compression moulding usually use a hydraulic press machine, and the cavity and core are fixed to the top and bottom platens. When the material is placed into the open mould, the platens close, the mould gets heated, and then the press pressure forces the SMC material to flow all over the mould.

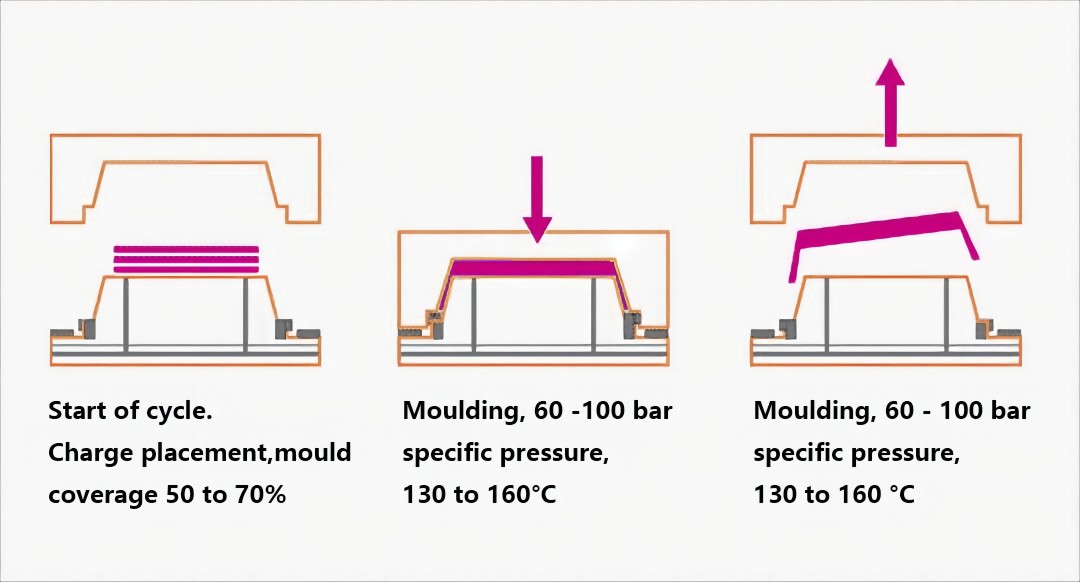

What is SMC compression moulding? SMC compression moulding is an advanced composite material moulding method. SMC moulding process is continuous and can produce high strength, complex parts in a wide variety of sizes. SMC moulding takes place in a device called “compression moulding press,” which is usually hydraulically powered. when the material charge is placed in the mould,the heated mould halves close and the pressure up to 2,000psi is applied. Cycle time ranges from one to five minutes, depending on the size and thickness of the part. Components such as ribs, bosses and inserts can be formed by compression molding. Compression moulding can be used to create even more complex, detailed SMC parts with great accuracy.

When we start to press SMC products, we first need to fix SMC tooling on the platen of the press, heat the SMC tooling, and then put the SMC material into the opening mold, setup SMC tooling molding process parameters such as pressure, curve time, opening&closing Speed, etc. Then, close the tooling. After the SMC tooling molded product is demolded, take out the product from SMC tooling.

As a China SMC mould manufacturer, MDC has been working on this field for a long time and has successfully developed projects such as SMC bathtub mould, SMC shower tray mould, SMC wash basin mould and so on. In the meantime, with the investment of the 4000T press machine, MDC is able to meet customers' requirements of try-out for parts even smaller than 3,500x3, 200MM. You can use our capabilities in mould design, mould making, and mould testing to meet your need. Our customers are Mercedes Benz, Audi, GM, etc.

Compression moulded SMC parts are characterized by their size and shape, excellent finished surfaces, and outstanding part-to-part repeatability.

2-CAVITY TRANSFER MOLD FOR 3P FD BASE

Some cases of SMC molds made by MDC

SMC mold heat treatment technology

How to manufacture and produce SMC molds more professional?

SMC materials are usually formed by the hot-compression process. This moulding process can be used to make a variety of products, including automotive parts, aerospace components, medical devices, and sports equipments. It can be used in a variety of applications such as:

SMC fiberglass is a glass reinforced with polymer resin, which makes it particularly strong and durable. It can be used in everything from aircraft parts to wind turbines, electronic equipment housings and more.

SMC consists of two layers of fiberglass cloth with epoxy adhesive sandwiched in between. The two layers are mechanically pressed together during the moulding process, which holds them together at the molecular level.

The process of making SMC fiberglass is similar to making any other types of fiberglass. The main difference is that the resins used in fiberglass contain more than one polymer molecule—usually styrene and acrylonitrile (SNAP), styrene-butadiene (SBR), or styrene ethylene butadiene (SEB).

The SMC manufacturing process is a method of manufacturing solid material composites using resins derived from thermoplastic polymers. The process consists of three basic steps: 1. Resin preparation 2. Fabrication 3. Curing

This plastic can be formed into the desired shape using an injection or compression moulding process.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China