Specialize in Compression molds

Specialize in Compression molds

Carbon fiber is a high-performance composite material known for its exceptional strength, light weight, and versatility. It is widely used across industries, from automotive to aerospace, due to its impressive mechanical properties. The two primary methods of carbon fiber manufacturing are wet carbon fiber and dry carbon fiber, each offering distinct benefits and applications. Understanding the differences between these processes is key to selecting the most appropriate method for your specific manufacturing needs.

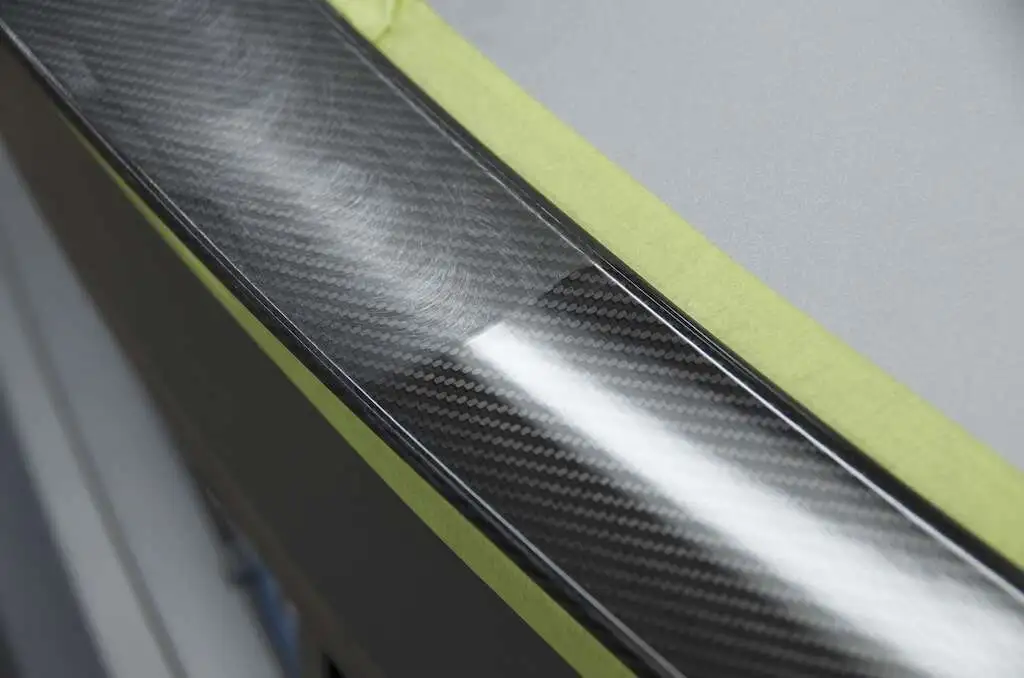

Wet carbon fiber, also known as resin-infused carbon fiber, involves the manual impregnation of carbon fiber cloth with epoxy resin. The "wet" terminology stems from the fact that carbon fibers are manually "wetted" with resin before being placed into molds for curing. This process can be done through methods such as resin infusion or hand lay-up.

The typical process for manufacturing wet carbon fiber components includes:

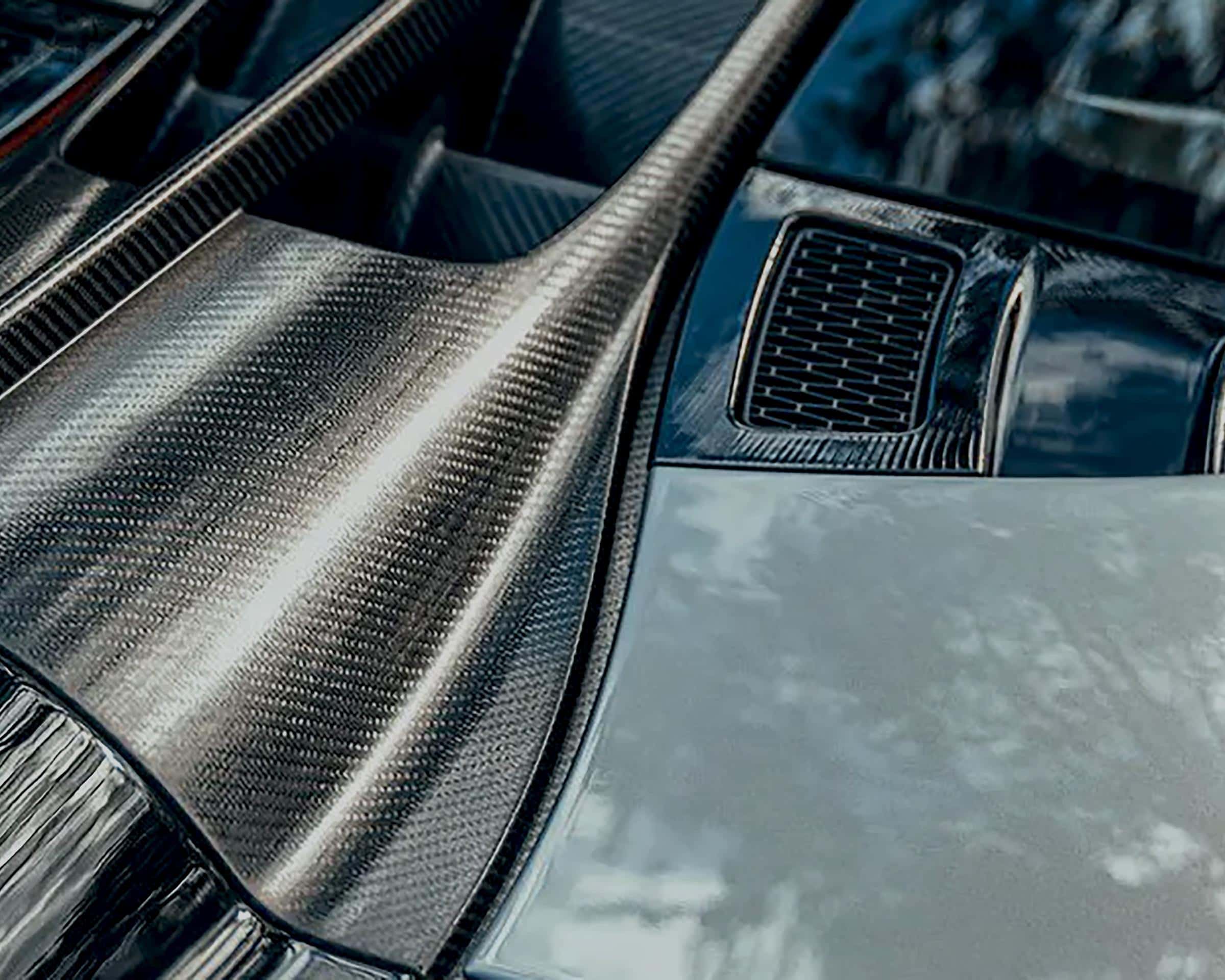

Dry carbon fiber, or prepreg carbon fiber, is made by pre-impregnating carbon fibers with resin at the factory. Unlike wet carbon fiber, there is no need for manual resin application, as the fibers are already impregnated with resin. This process requires more specialized equipment, such as high-pressure autoclaves, to cure the components.

The dry carbon fiber manufacturing process follows these steps:

When it comes to choosing between wet and dry carbon fiber, it's crucial to consider the specific requirements of your project. Both methods have their place in composite manufacturing, but understanding their differences can help you make a more informed decision.

| Aspect | Wet Carbon Fiber | Dry Carbon Fiber |

|---|---|---|

| Cost | Lower cost, ideal for low-volume production | Higher cost due to specialized equipment and materials |

| Strength and Durability | Moderate strength, suitable for non-structural applications | Superior strength, ideal for high-performance components |

| Precision | Lower precision due to manual processes | High precision and consistency in part manufacturing |

| Production Speed | Faster, suitable for prototyping and small batches | Slower due to autoclave curing, ideal for mass production |

| Applications | Non-critical parts like enclosures, panels | High-performance parts like aerospace components, automotive frames |

Another widely used method for producing carbon fiber parts is compression molding, which is ideal for high-volume production of composite molds. In this process, carbon fiber sheets (often prepreg materials) are placed in a heated mold, and pressure is applied to form the desired shape.

While compression molding can provide similar strength and precision to dry carbon fiber processes, it offers a more cost-effective solution for large-scale manufacturing. However, the level of detail achievable in compression molding may not be as high as that produced by dry carbon fiber techniques.

The decision between wet and dry carbon fiber depends on your specific manufacturing requirements, including cost constraints, performance needs, and production scale. Wet carbon fiber offers a budget-friendly solution for larger components, while dry carbon fiber delivers superior performance for high-end applications. Additionally, techniques like compression molding provide an efficient alternative for mass production of carbon fiber components.

Whether you are looking to manufacture automotive parts, aerospace components, or consumer goods, understanding the differences between these carbon fiber processes and selecting the right one can ensure optimal results for your project.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China