Specialize in Compression molds

Specialize in Compression molds

The SMC mold made of SMC material has excellent electrical insulation properties, mechanical properties, thermal stability, and chemical corrosion resistance. Therefore, the application range of SMC mold is quite wide, mainly in the following application areas:

Developed countries such as Europe, the United States, and Japan have adopted a large number of SMC composite materials in automobile manufacturing, involving all types of cars, passenger cars, trains, tractors, motorcycles, and sports vehicles, agricultural vehicles, etc. The main SMC molds include the following categories :

1.1 Suspension parts: front and rear bumpers, instrument panels, etc.

1.2 Body and body parts: body shell, hard shell roof, floor, door, radiator grille, front end panel, spoiler, luggage compartment cover, sun hood, SMC fender, engine cover, large Lamp reflector.

1.3 Parts under the engine cover: such as air conditioner shell, air guide cover, intake pipe cover, fan guide ring, heater cover, water tank parts, brake system parts, battery bracket, engine sound insulation board, etc.

SMC railway vehicle window frames, toilet components, seats, coffee table tops, SMC compartment wall panels and SMC roof panels, etc.

3.1 Water tank

3.2 Bath supplies

3.3 Purification tank

3.4 Building template

3.5 Storage room components

The application of SMC mold in electrical industry and communication engineering mainly includes the following parts.

4.1 Electrical enclosure: including electrical switch box, SMC electrical wiring box, instrument panel cover, etc.;

4.2 Electrical components and electrical components: such as SMC insulators, insulating tools, motor end caps, etc.;

With the improvement of people's living standards, showering after work has become a part of life. In Japan, 2.2 million households are newly built or renovated every year, making the construction industry booming, especially for bathtubs, overall bathroom equipment, sinks and other products that use SMC molds in large quantities, and such products are developing towards large-scale and advanced development , The shower equipment made by SMC moulds can give people a visual and tactile enjoyment, and the price can be competitive with ceramic tile or enamel products, and there are many shapes. It is a streamlined beauty everywhere, and has become a necessity for future families. SMC mold has the following advantages:

5.1 The product can have various bright and bright colors.

5.2 One-piece molding, the product design has no seams, which is satisfactory in terms of safety or comfort.

5.3 There are no restrictions on product size and shape.

5.4 The combination is fast and lightweight.

5.5 The product has good strength and is not easy to break or fade.

5.6 The surface of the product is smooth and the heat preservation is good.

5.7 Its products can be produced on a large scale.

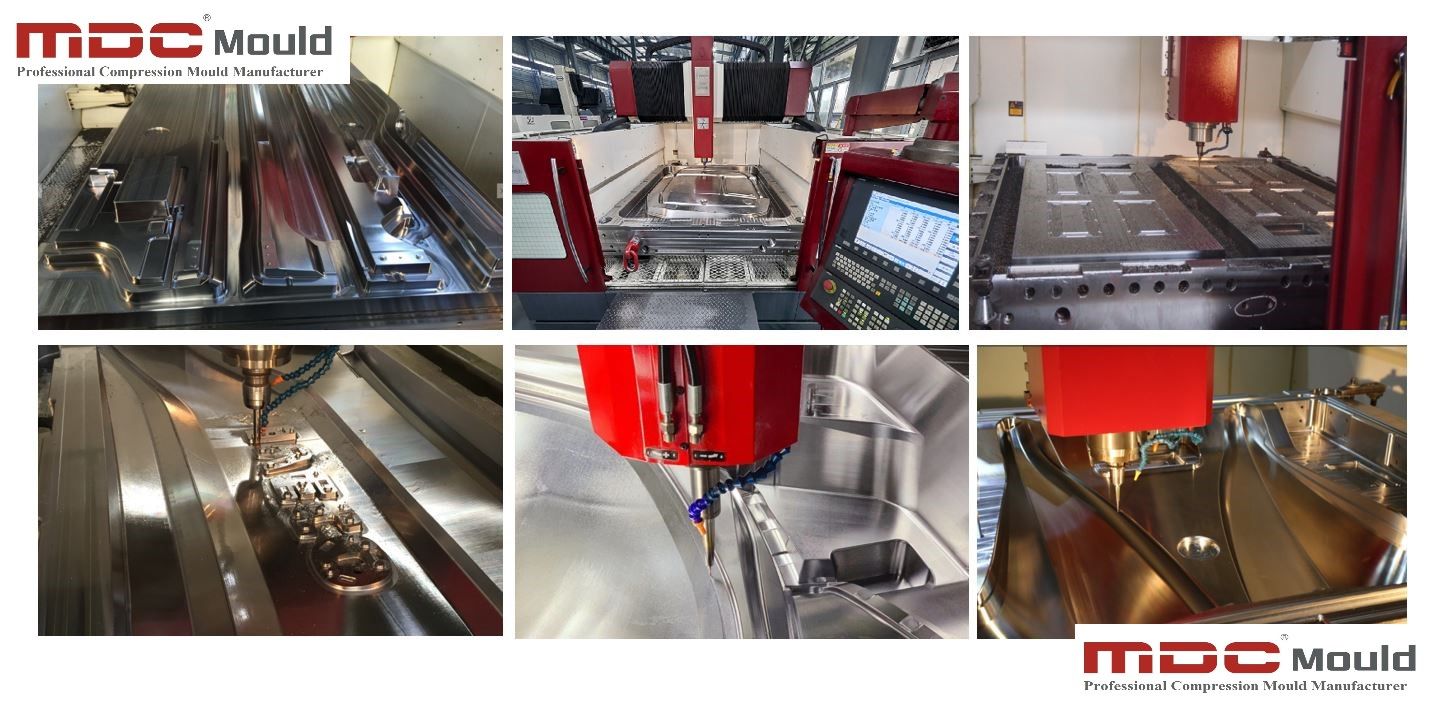

MDC Mould is a professional supplier of SMC materials. The SMC moulds produced by MDC Mould are appreciated by our customers. If you have this demand, you can contact us and we will manufacture products that satisfy you!

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China