Specialize in Compression molds

Specialize in Compression molds

Compression tools are essential for shaping materials and ensuring good results in industrial and manufacturing processes. They're used in compression molding, compression sealing, and compression crimping, and they're key to getting consistent, precise results in many different applications.In this article, we'll look at what compression tools are, the types you can use, how they're used, and their benefits, with a focus on their use in manufacturing.So, what even are compression tools?

A compression tool is any device or mechanism that uses pressure or force to make a material take the shape of a mold. This concept isn't limited to just one industry; it covers various processes, like compression molding, compression crimping, and compression sealing. The tool usually operates by applying controlled pressure to a material, forcing it to take the shape of the mold or ensuring a tight connection. There are different types and sizes of compression tools, like hydraulic compressors, mechanical compressors, and manual compression tools.

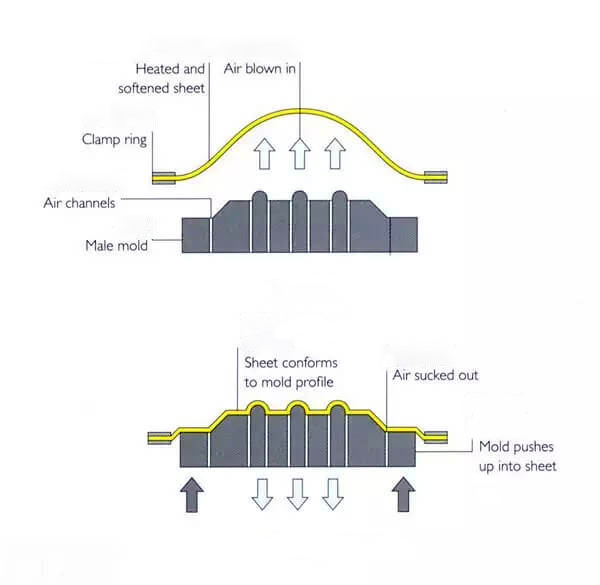

In compression molding, a compression tool is used to shape thermosetting plastics or rubber by applying heat and pressure. This process involves placing a pre-measured amount of material into a heated mold cavity, and then the compression tool applies pressure to the material, forcing it to take the shape of the mold.This process is great for creating automotive parts, electrical components, and consumer goods like bumpers, gaskets, and seals.

Compression crimping tools are used to join two materials, like metal wires and connectors, by compressing the connector around the wire. This process is especially important in electrical and telecommunications industries, where the quality of electrical connections is vital for safety and performance. A reliable connection can prevent electrical faults and short circuits.

Compression sealing tools are essential for applications requiring a tight seal between two surfaces. These tools apply pressure to a seal or gasket, ensuring that it fills the gap between parts and prevents leakage. Whether you're working on plumbing, HVAC systems, or fluid pipelines, these tools make sure everything stays leak-free and lasts a long time.

In compression molding, the compression tool is key to making sure the material fills the mold cavity completely. The tool heats and presses the material, forcing it into every part of the mold. This results in a perfectly formed part with consistent dimensions, making compression molding great for producing complex parts in large quantities.

In compression crimping, the tool securely attaches connectors to wires, which is essential for creating safe electrical connections. By pressing the connector onto the wire, the tool creates a solid, permanent connection that ensures minimal electrical resistance and maximum conductivity. The process is critical for the reliability of electrical systems in industries ranging from automotive to telecommunications.

When you're sealing something up, you can use compression tools to make sure that the seal or gasket is pressed into the joint properly. This helps to prevent fluid, gas, or air from leaking out. The tools apply consistent pressure to the sealing material, making sure that the connection is tight and durable. This process is really important in plumbing, HVAC systems, and fluid control applications, because if there are leaks, it can lead to inefficiency or even safety hazards.

Compression molding tools are used a lot in the automotive industry to make parts like bumpers, seals, and gaskets. Using high-quality compression tools makes sure these parts meet the strict standards for strength, durability, and consistency that the automotive sector requires.

Compression crimping tools are key in the electrical industry for securing those all-important electrical connections.Proper crimping ensures that wires and terminals are firmly connected, reducing the risk of electrical faults and improving safety in electronic devices, machinery, and telecommunications systems.

Compression sealing tools are key for making sure plumbing and HVAC systems are watertight and airtight. These tools help prevent leaks in pipes, valves, and fittings, which leads to energy efficiency and reliability.

Compression tools are used in the aerospace and defense industries to mold composite materials into parts that have to be able to handle extreme conditions. The precision and durability offered by compression tools make sure that critical components, like aircraft parts and military equipment, can be relied on.

A compression tool is a must-have for any business that works with materials like plastics, metals, and wires. Whether it's for compression molding in the auto industry or crimping wires in electrical systems, these tools are top-notch. They're super precise, efficient, and cost-effective. When manufacturers get to know the different types of compression tools and how to use them, they can step up their processes, save some cash, and make top-notch products. If you're into molding, crimping, or sealing, the right compression tool will get the job done right and keep things running smoothly from start to finish.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China