Specialize in Compression molds

Specialize in Compression molds

BMC is an acronym for Bulk Molding Compound. Since it is usually mixed in a dough-like form, rather than as a sheet, BMC is also called DMC. It is made of resins (such as unsaturated polyesters, epoxy resins, phenolic resins, etc.), glass fibres, fillers and other additives. It can be adjusted by changing the added material according to the required properties. It is usually made into stripes to facilitate moulding and is widely used in many industrial fields.

BMC and SMC(sheet molding compound) are similar in composition. But for BMC moulding, firstly, it should be mixed the polyester resin and additives. After this step, it becomes a resin mixture, and then adds the filler. Next, reduce the mixing speed of the "premix" to prevent the glass fiber from cracking. If the material needs to be further concentrated, a thickener should be added. This material can be used for compression moulding and injection moulding.

The development history: In the early 1960s, BMC materials were developed by British BIP Company and American R&H Company with low shrinkage and non-shrinkage BMC, which greatly improved the dimensional stability, smoothness and appearance of the material. Polyester moulded plastic. In the 1970s, applications requiring dimensional accuracy, high rigidity and heat resistance, such as office machine stand. In the mid-1980s, to expand the range of applications, freely colourable BMCs were developed.

Proportionally, the BMC material is mainly composed of three parts. It consists of matrix resin - unsaturated polyester resin and low shrinkage system, reinforcing material - mainly glass fibre, filler - calcium carbonate, talc, aluminium hydroxide, china clay, etc. Although the amount of these components account for a small proportion of the total components, they play a very special role in the formulation system of BMC. They will have an important impact on the preparation process, product moulding and final properties of BMC.

The reinforcement material of BMC is mainly chopped glass fibre, which is an important guarantee for the mechanical properties of BMC. The chopped fibre lengths used in BMC are generally 6.4mm and 12.7mm. The content of BMC glass fibre depends on the strength requirements of the product, but too high or too low glass fibre content will increase the difficulty of production and moulding, generally controlled between 50% and 55%. BMC has lower glass fibre content than SMC, shorter fibre length and higher filler loading than SMC.

Unsaturated polyesters are polycondensates formed by the reaction of polyols (also known as polyols), organic compounds with multiple alcohols or hydroxyl functional groups, and unsaturated and, in some cases, saturated diacids. Typical polyols used are ethylene glycol, propylene glycol, and diethylene glycol; typical acids used are phthalic acid, isophthalic acid, terephthalic acid, and maleic acid anhydride.

Low shrinkage mechanism: incompatible types - polyethylene, polyvinyl chloride, etc., to improve the surface roughness of the product; for pre-cured compatible types - thermoplastic polyester, polyvinyl acetate, polymethyl methacrylate etc., can achieve true zero shrinkage or even negative shrinkage.

The initiators used in BMC are mainly high-temperature initiators, which have long storage life and function at high temperatures. Some peroxides are commonly used, such as BPO (dibenzoyl peroxide, TBPB (benzoic acid peroxide), tert-butyl ester), etc. To improve production efficiency and reduce the moulding temperature, two different initiators can be used simultaneously, which is a new curing system. However, it may shorten the shelf life of BMC. It can improve the curing speed, Reduce the moulding temperature to meet some special requirements of the product, such as excessive temperature will damage the product. The dosage is generally about 1%.

When the resin is mixed with other raw materials to form the resin slurry, the viscosity needs to be kept low for good wetting with the glass fibres. After the BMC production is completed, the viscosity of the sheet needs to increase rapidly to achieve a very high viscosity.

A release agent must be added to release the BMC moulded product smoothly. The one coated on the surface of the mould is called the outer release agent, and the one added to the resin paste is called the inner release agent. The release agent in the mould is some long-chain fatty acid salts whose melting point is lower than the moulding temperature and is cured when the material is heated. It will melt and migrate to the product's surface before the mould is isolated from the product to achieve the demoulding effect. Commonly used internal release agents are zinc stearate (ZnSt), calcium stearate (CaSt) or fluorine.

The colourant refers to the colourant, which makes the BMC have a variety of desired colours and makes the SMC product more vibrant. The pigment is not an ordinary colourant because the BMC is moulded at a high temperature; the choice of the colourant is very important. However, common colourants will appear in colour separation, fading and other phenomena in high temperature and high-pressure flow.

In addition to the above-mentioned main components in the BMC components, some trace auxiliaries, such as reverse phase separation agents, viscosity reducers, low shrinkage additives, polymerization inhibitors, etc., need to be added according to the special requirements of products and processes.

Why choose chopped fiber bulk molding compounds? Bulk molding compounds offer several advantages over metal.

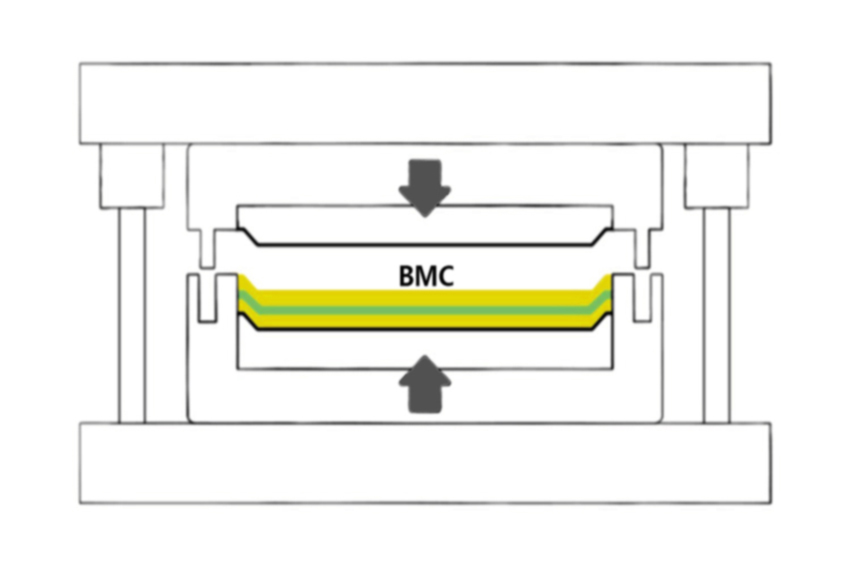

First of all, put a certain amount of prepared material into the preheated BMC mould. Then close the mould at a certain speed, the material will flow under the pressure and fill the entire cavity. Then keep it at the required temperature and pressure for a certain time. When the physical and chemical processes have been completed to solidify, shape and achieve the best performance, we can open the mould and take out the product. In the whole BMC compression moulding process, what directly affects the quality and accuracy of BMC parts is the temperature. BMC mould can be divided into oil heating, electric heating, and steam heating. No matter how demanding your products are, MDC has the ability to design and manufacture the mould.

BMC compression molding is a cost-effective solution for small/large structural components. The process is used in high volume manufacturing and has detailed/complex shapes, thus avoiding the use of auxiliary parts in the assembly.

The use of lightweight short-cut fiber compression-molded BMCs reduces weight compared to aluminium parts. As a China high-quality BMC mould company, MDC Mould has already manufactured a lot of BMC moulds and BMC products. So MDC have rich theoretical knowledge and production experience in BMC moulding field and can customize a complete set of BMC moulding line for you. BMC products of MDC cover a wide range of areas. For Example, the electrical industry and automobile industry, such as BMC taillight cover mould, BMC electrical box mould, BMC meter box mould and BMC manhole cover mould, etc.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China