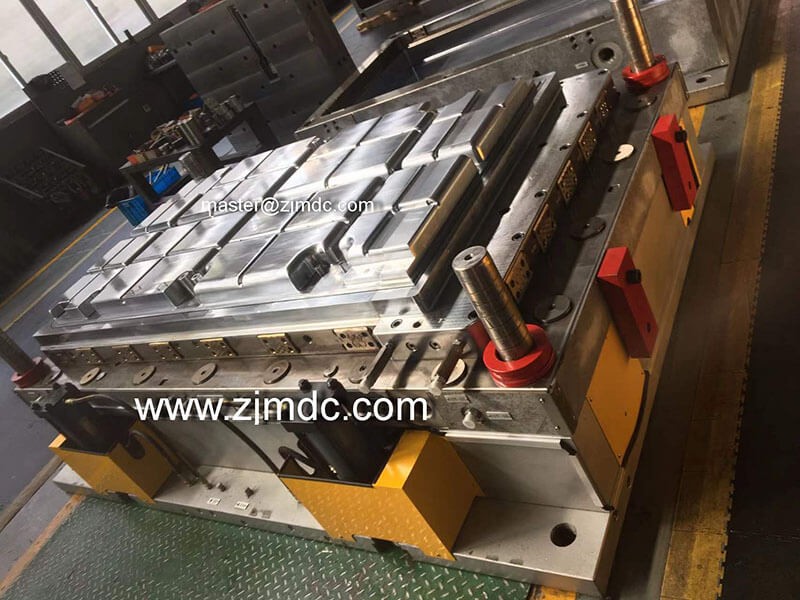

Specialize in Compression molds

Specialize in Compression molds

In modern architecture and home design, composite baseboard trim and composite trim boards are becoming increasingly popular. These materials provide a durable, stylish, and low-maintenance alternative to traditional wood trims. They are ideal for both residential and commercial spaces.

Composite trim is manufactured from a combination of wood fibers, plastic resins, and bonding agents. These materials are molded or extruded into various profiles suitable for interior and exterior applications.

Composite trim is ideal for:

Composite trim can be installed using traditional woodworking tools. Steps include:

| Feature | Composite Trim | Wood Trim |

|---|---|---|

| Moisture Resistance | Excellent | Poor |

| Durability | High | Moderate |

| Maintenance | Low | High |

| Appearance | Wood-like, consistent | Natural, variable |

| Cost | Higher upfront | Lower upfront, higher long-term |

Composite trim boards come in:

Many composite trims are made with recycled materials, making them a sustainable option. Their longevity also reduces replacement frequency, conserving resources over time.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China