Specialize in Compression molds

Specialize in Compression molds

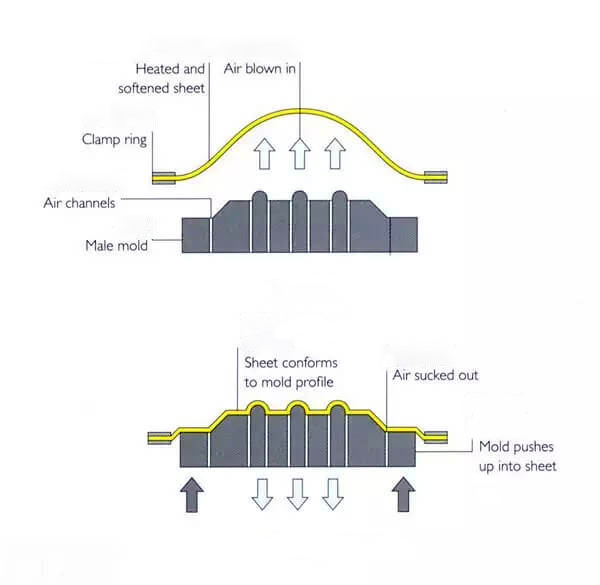

Thermoforming is a widely used process in the manufacturing industry, especially when producing plastic components. The process involves heating a plastic sheet until it becomes pliable and then shaping it against a mold. In thermoforming, the mold type plays a crucial role in determining the final product’s quality, accuracy, and surface finish. Two primary types of molds are used in this process: the positive mold (also known as the male mold) and the negative mold (also known as the female mold). Understanding the differences between these molds is essential for anyone involved in thermoforming or related fields such as composite mold and compression mold manufacturing.

A positive mold, or male mold, is a type of mold where the material is formed over the exterior surface. The mold itself represents the shape that will be transferred to the inner surface of the final product. This means that the material is stretched over the mold, with the exterior of the material taking the shape of the mold's exterior.

A negative mold, or female mold, is the inverse of a positive mold. In this case, the material is drawn into the mold, allowing the outer surface of the material to match the mold’s interior. The external surface of the final product mirrors the internal surface of the negative mold.

Both positive and negative molds have their advantages and limitations, and the choice between them depends on the specific requirements of the application.

The principles of positive and negative molds extend beyond traditional thermoforming into the realm of composite molding. In composite molds used for producing high-performance parts, such as carbon fiber molds, the choice between positive and negative molds can impact the final part’s structural integrity and surface quality.

Understanding the difference between positive and negative molds in thermoforming is essential for optimizing the manufacturing process. Positive molds provide high-quality internal surfaces but can lead to material thinning, while negative molds offer uniform material distribution and superior external finishes. Whether in traditional thermoforming or advanced composite molding applications, choosing the right mold type is crucial for achieving the desired product characteristics. As technologies evolve, the principles behind positive and negative molds continue to shape industries ranging from packaging to aerospace, highlighting their ongoing importance in manufacturing.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China