Specialize in Compression molds

Specialize in Compression molds

MDC Mould, a leading manufacturer specializing in SMC (Sheet Molding Compound) molds, unveils the intricate process behind SMC molding, revolutionizing the manufacturing industry.

SMC material has emerged as a preferred choice in composite manufacturing due to its exceptional properties and versatility. Comprising thermosetting resin, chopped glass fibers, fillers, and additives, SMC material offers a unique combination of strength, dimensional stability, and resistance to various environmental factors.

The SMC molding process begins with the preparation of the SMC material. The constituents are meticulously blended, creating a thick paste or sheet ready for molding. MDC Mould utilizes advanced techniques to ensure precise mixing and consistent material quality.

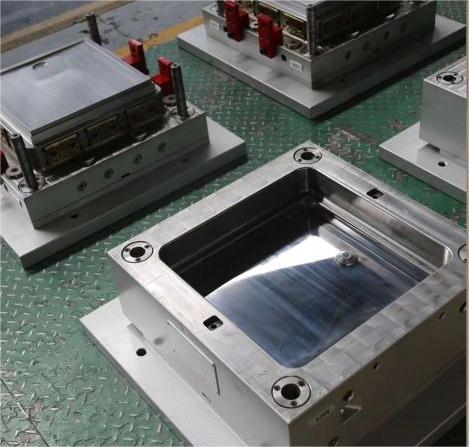

Once the SMC material is prepared, it is loaded into a mold cavity. The mold, typically consisting of two halves, is meticulously designed to accommodate the desired shape and intricacies of the final product. MDC Mould's expertise lies in the design and production of high-quality molds tailored to specific applications.

With the mold cavity filled, the two halves of the mold are closed tightly, enclosing the SMC material. The next crucial step involves applying heat and pressure. MDC Mould employs state-of-the-art compression molding equipment to ensure optimal curing and bonding of the SMC material.

During the curing process, the thermosetting resin undergoes a chemical reaction, crosslinking and hardening the SMC material. This results in a solid, durable composite structure with enhanced mechanical properties. MDC Mould's commitment to precision and efficiency ensures the formation of flawlessly molded parts.

After the curing and solidification stage, the mold is cooled down, allowing the SMC material to retain its shape and dimensions. The cooled mold is then opened, and the solidified SMC part is carefully removed. MDC Mould's attention to detail guarantees the integrity and quality of the final product.

Post-molding, the SMC parts may undergo additional processes, such as trimming, finishing, painting, or assembly, depending on the specific application requirements. MDC Mould's comprehensive capabilities enable them to offer end-to-end solutions, meeting diverse customer needs.

The advantages of SMC material and the precision of the molding process make it an ideal choice for various industries, including automotive, aerospace, electrical, and construction. The lightweight yet robust nature of SMC parts contributes to improved fuel efficiency, structural integrity, and overall product performance.

MDC Mould, with its extensive experience in SMC molding technology, continues to drive innovation in mold manufacturing. By harnessing the unique properties of SMC material, MDC Mould delivers precision, durability, and efficiency, empowering industries to achieve new heights of success.

MDC Mould is a renowned manufacturer specializing in SMC molds. With a commitment to excellence, MDC Mould designs and produces high-quality molds for a wide range of applications. Leveraging advanced SMC molding technology, MDC Mould continues to redefine the manufacturing landscape through precision, innovation, and unmatched customer satisfaction.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China