Specialize in Compression molds

Specialize in Compression molds

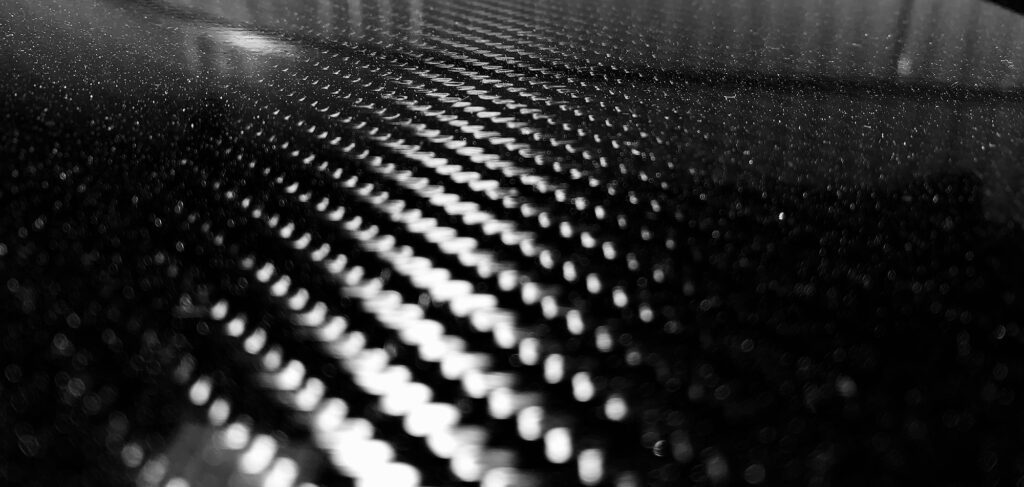

Carbon fiber is renowned for its exceptional strength-to-weight ratio, making it a preferred material in aerospace, automotive, and sports equipment industries. Laying carbon fiber in a mold requires meticulous attention to detail and a precise technique to ensure the final product meets the desired specifications. This guide will walk you through the process of , from preparation to finishing touches, ensuring your project is a success.

Measure and cut the carbon fiber fabric to fit the mold. Ensure precise cuts to minimize waste and overlaps. Cutting at a 45-degree angle to the weave can help in achieving better conformity to the mold’s shape.

For enhanced strength and a better finish, consider using a vacuum bagging system. Place a peel ply over the final layer of carbon fiber, followed by a perforated release film and a breather layer. Enclose the setup in a vacuum bag and use a vacuum pump to remove air and compress the layers, ensuring a void-free laminate.

Allow the resin to cure according to the manufacturer’s specifications. This could range from room temperature curing to elevated temperature curing in an oven. Ensure the part remains undisturbed during this period to avoid defects.

Once cured, carefully remove the vacuum bagging materials and peel ply. Gently separate the part from the mold using plastic wedges or demolding tools. Avoid using metal tools to prevent damaging the mold or the part.

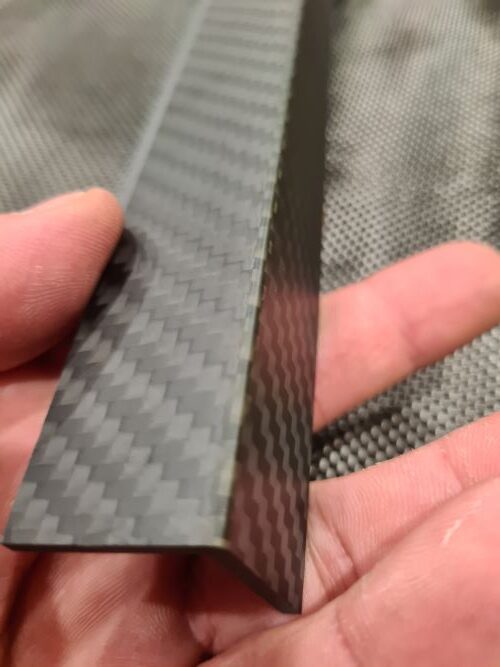

Trim any excess material from the edges of the part using a rotary tool or diamond-tipped saw. Sand the edges to smooth out any rough areas and achieve the desired finish.

Inspect the part for any defects or imperfections. If necessary, apply a clear coat or UV-protective layer to enhance the appearance and durability of the carbon fiber.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China