Compression Molding and Forming: A Beginner's Guide

Join Date: 2025-03-15

Discover the fundamentals of compression molding, key techniques, and essential tips for achieving high-quality results.

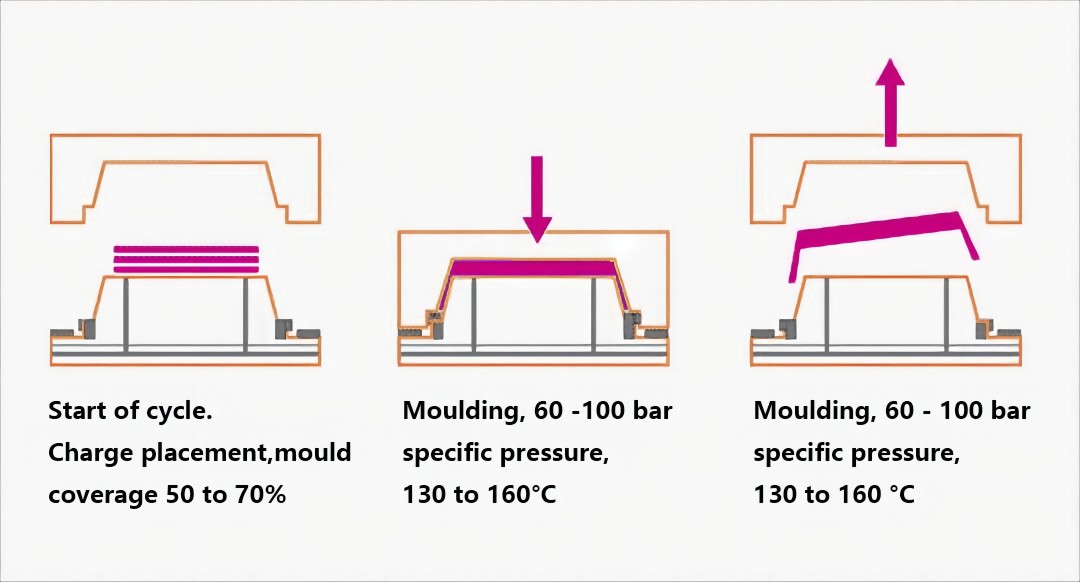

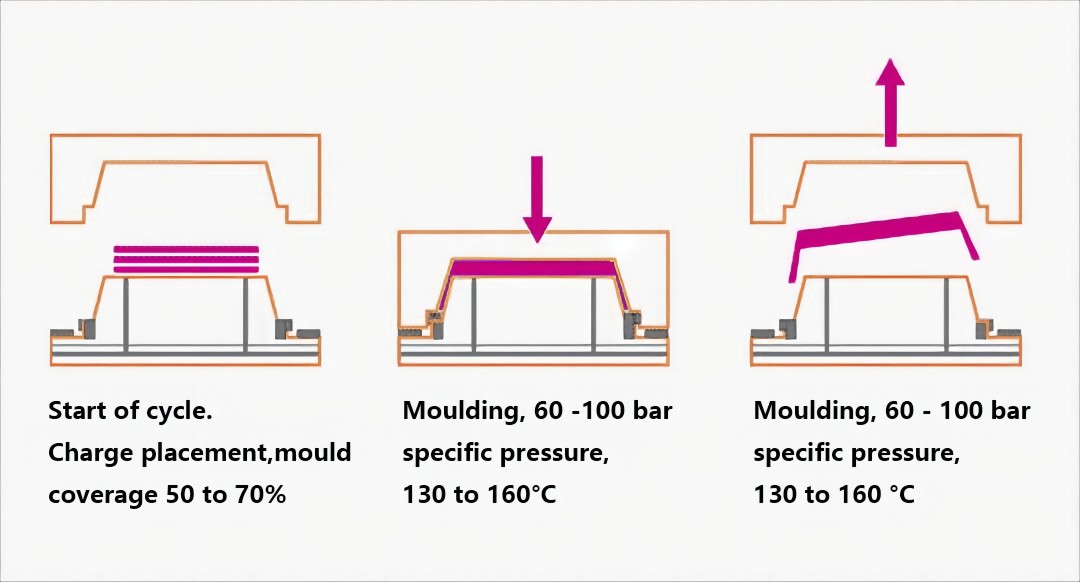

Key Steps in the Compression Molding Process

-

Material Preparation: Preheat materials like SMC, BMC, or rubber for better flow and faster curing.

-

Mold Loading: Proper material placement ensures uniform pressure and prevents defects.

-

Compression and Curing: Heat and pressure are applied to shape and solidify the material.

-

Cooling and Demolding: Controlled cooling reduces shrinkage and enhances dimensional stability.

-

Trimming and Finishing: Flash removal, sanding, and coating improve the final product.

Common Materials for Compression Molding

|

Material

|

Characteristics

|

Applications

|

|

SMC (Sheet Molding Compound)

|

High strength, corrosion resistance

|

Automotive parts, electrical enclosures

|

|

BMC (Bulk Molding Compound)

|

Heat resistance, dimensional stability

|

Appliance parts, electrical components

|

|

Rubber

|

Flexible, durable under pressure

|

Seals, gaskets, vibration dampers

|

|

Carbon Fiber Composites

|

Lightweight yet extremely strong

|

Aerospace, automotive, performance parts

|

Advantages of Compression Molding

-

Cost-Effective: Ideal for large parts with minimal material waste.

-

High Strength and Durability: Ensures robust products for demanding applications.

-

Complex Geometries: Capable of producing intricate designs with precise details.

-

Excellent Surface Finish: Provides smooth, high-quality surfaces that require minimal post-processing.

Challenges in Compression Molding

-

Longer Cycle Times: Thermoset materials often require extended curing periods. Optimizing mold temperature reduces delays.

-

Material Waste: Flash removal is necessary but can be minimized with precise mold design.

-

Tooling Costs: While initial costs are higher, durable molds offset these expenses in high-volume production.

Expert Tips for Beginners

-

Choose the Right Material: Select materials like SMC, BMC, or rubber based on your product’s durability and finish needs.

-

Optimize Mold Design: Add proper venting to improve pressure distribution and reduce trapped air.

-

Control Temperature and Pressure: Fine-tune these settings for consistent quality and reduced cycle times.

-

Prioritize Mold Maintenance: Regular cleaning and lubrication enhance mold longevity.

Applications of Compression Molding

Compression molding is a versatile method used in various industries for producing durable, complex parts.

-

Automotive: Engine covers, battery enclosures, and body panels.

-

Electrical: Switchgear, insulators, and circuit breaker housings.

-

Aerospace: Lightweight carbon fiber composite parts for enhanced performance.

-

Consumer Goods: Kitchen appliances, furniture parts, and sporting equipment.

Conclusion

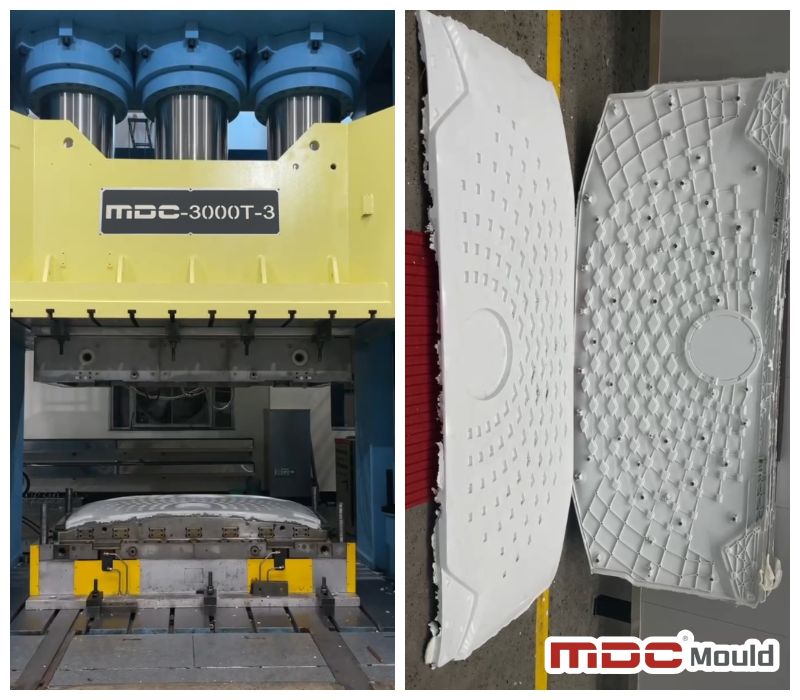

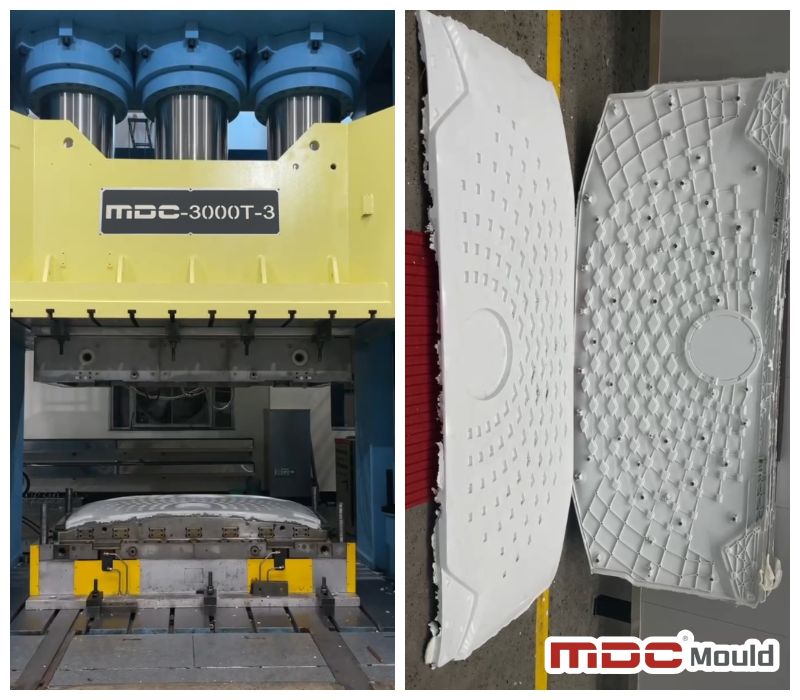

Compression molding is a powerful solution for creating durable, complex parts across multiple industries.

For precise, high-performance molds, trust MDC Mould for professional solutions tailored to your needs.

Mastering compression molding techniques and material selection ensures faster production cycles, improved quality, and reduced costs.