Specialize in Compression molds

Specialize in Compression molds

Sheet Molding Compound (SMC) is made by prepreg. SMC is a resin paste of unsaturated polyester resin added with thickeners, inorganic fillers, initiators, mold release agents and pigments, impregnated with chopped glass fibers or felt sheets, and covered with polyethylene films on both sides. plastic. This is a new type of thermosetting FRP molding material developed in the 1960s.

The composition of the sheet molding compound is substantially the same as that of the bulk molding compound. Due to the different properties required by the materials, including process properties, mechanical properties and other special properties, and different preparation processes, there are differences in the selection and proportion of components. Compared with the bulk molding compound, the filler content in the sheet molding compound is lower, and the glass fiber content used is relatively high (20% ~ 35%), the length is relatively long (25 ~ 50mm), and the physical and mechanical properties are good.

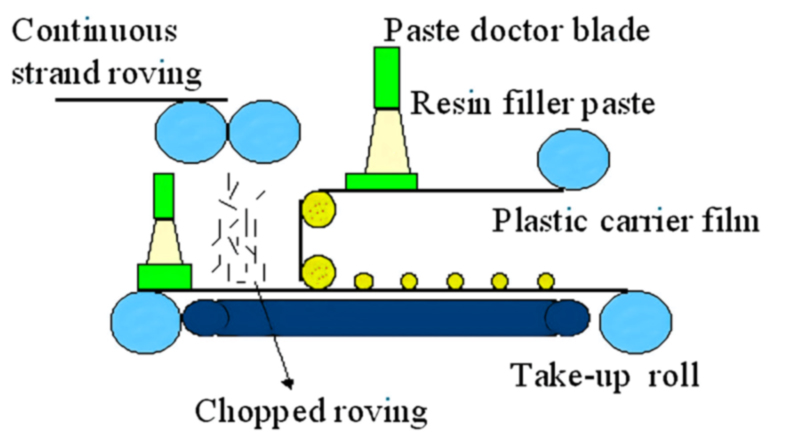

The strength of SMC can be improved by increasing the fiber content and fiber length. The production of SMC is a continuous process. According to the different reinforcing materials used, it can be produced in different ways. At present, glass fiber roving is mostly used.

The sheet molding compound manufacturing process usually consists of two stages. First, thickeners, low shrinkage additives, fillers, mold release agents, colorants and other components are added to the unsaturated resin, and then mixed to form a resin paste. Impregnated sheet-like strong materials such as chopped glass fiber blankets in the molding machine (covered with polyethylene film on both sides), and then rolled to make them compact by pressing rollers, and then dried to form felt sheets. When using, tear off the film, cut the laminate according to the size of the finished product, put it into the SMC mold for heating and pressure, and obtain the final SMC part after a certain period of time.

The SMC production process mainly includes the following 4 steps:

Resin paste refers to the components other than the reinforcing material (glass fiber) being thoroughly mixed in advance to make it a paste-like mixture. There are two methods for its preparation, one is a batch mixing method, and the other is a continuous metering mixing method.

The cutter of the roving is located in the upper part of the unit, and the whole process of cutting and settling is carried out in a closed space. The cutter generally adopts a three-roller structure. In order to make the chopped roving settle evenly, a beater or blowing air can be set under the cutter. In the process of roving cutting and settling, the most attention should be paid to the static electricity problem. Severe electrostatic effect will cause the rovings on the yarn path to be entangled with each other, and it is easy to adhere to the side wall or roll entanglement after cutting, which greatly affects the uniformity of fiber distribution.

At the end of the SMC production line, various types of rolls (such as flat rolls, groove rolls, piercing rolls and spiral rolls, etc.) are arranged on the equipment. When the sheet passes through the upper, lower and surrounding areas of these rollers, the kneading action of each roller on the sheet causes the fibers to be saturated with resin, discharges air bubbles, and compresses the sheet to a uniform thickness. There are two types of impregnation and compaction structures in general production lines, namely the multi-roller ring groove pressing roller type and the curved double belt type of the conveyor belt.

When the SMC sheet is produced, it takes a certain curing period to increase the viscosity of the sheet to the viscosity range required by the molding compound, and then it can meet the needs of compression molding. SMC sheets are usually stored for 1 to 2 weeks at room temperature to complete this process. In order to make the sheet reach the best molding viscosity as soon as possible and accelerate its aging, it is usually treated in a thickening chamber with a higher temperature (about 40°C) for 1 to 3 days. At present, the more advanced method is to add a thickening zone in the SMC production line or use some high-efficiency thickeners, which enables the SMC sheet to be molded after it is made.

SMC has the advantages of superior electrical properties, corrosion resistance, light weight and flexible engineering design, and its mechanical properties can match that of some metal materials, so it is widely used in transportation vehicles, construction, electronics/electrical and other industries. MDC mould has rich manufacturing experience in SMC, which has been highly praised by many customers.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China