Specialize in Compression molds

Specialize in Compression molds

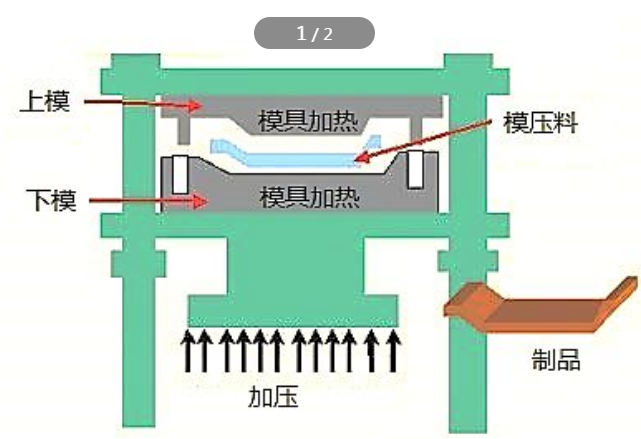

Hot pressing mould has the advantages of simple structure, low manufacturing cost, low molding pressure and high precision of microstructure replication. Especially in the mold processing of microfluidic machinery, micro-optics devices, microfluidic chips and other fields, hot pressing technology has a broad application prospect. However, there are still some problems when using hot pressing technology to make molds, such as demoulding defects caused by uneven cooling in the demoulding process. Therefore, the reasonable design of hot pressing die, high precision manufacturing and process improvement have become the key to improve the quality of hot pressing products.

A hot pressing die is a reproduction technology that transfers structural material from the die to a polymer substrate by hot pressing at appropriate temperature and pressure. According to the different contact mode between the mold and the substrate in the transfer process, the hot pressing process can be divided into three types, namely, flat pressing, stepping and rolling.

1.flat pressing hot pressing process

The flat hot pressing process is made by pressing the die flat on the substrate surface and transferring and replicating all the characteristic structures on the die in one treatment cycle.

2.step type hot pressing process

The production process of the stepping hot pressing process is that after the transfer of the large area substrate, the small area mold moves to the next position and repeats the hot pressing process.

3.rolling hot pressing process

The rolling hot pressing process is divided into two kinds, one is the roller -- the plate, the other is the roller -- the roller. When designing roller - plate hot pressing die, the plate die can be placed on the substrate and then rolled with smooth roller. When designing roller - roll hot pressing molds, the surface of a plate mold can be structurally machined and then bent and fixed to the roller, but joint gaps should be avoided as this can lead to periodic discontinuous impressions.

MDC mould is a local hot pressing mould manufacturer in China. The moulds manufactured by the company can fully meet the quality requirements of global top 500 enterprises, and the technology has reached the international synchronization level. In recent years, the company is committed to the development and manufacture of various GMT, LFT moulds and carbon fiber and other lightweight composite material moulds. And through the joint development and technical exchanges with international well-known manufacturers, learn and understand all kinds of new composite material production technology concepts, such as as a representative of new composite materials, such as: Symalite, LWRT, GMTEX and other molds, MDC is a global professional manufacturer of various die pressing enterprises. Welcome customers to consult!

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China