Specialize in Compression molds

Specialize in Compression molds

As an important composite material mold, SMC mould is widely used in automobile, aerospace, electronics and other fields. Its production process requires strict control of parameters such as the size, shape, and position of the mold to ensure stable and consistent product quality. However, traditional measurement methods, such as manual measurement and traditional measuring instruments, have problems such as low measurement accuracy and low measurement efficiency, which are difficult to meet the requirements of SMC mold production. And advanced measuring equipment and instruments, such as Three coordinate measuring instrument, have been widely used in the production of SMC molds due to their high precision, high efficiency and multi-functional characteristics.

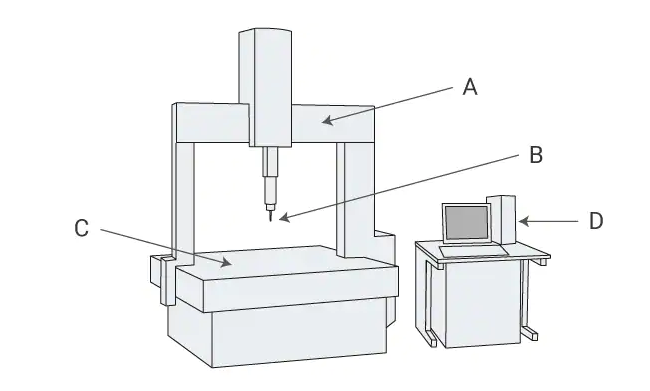

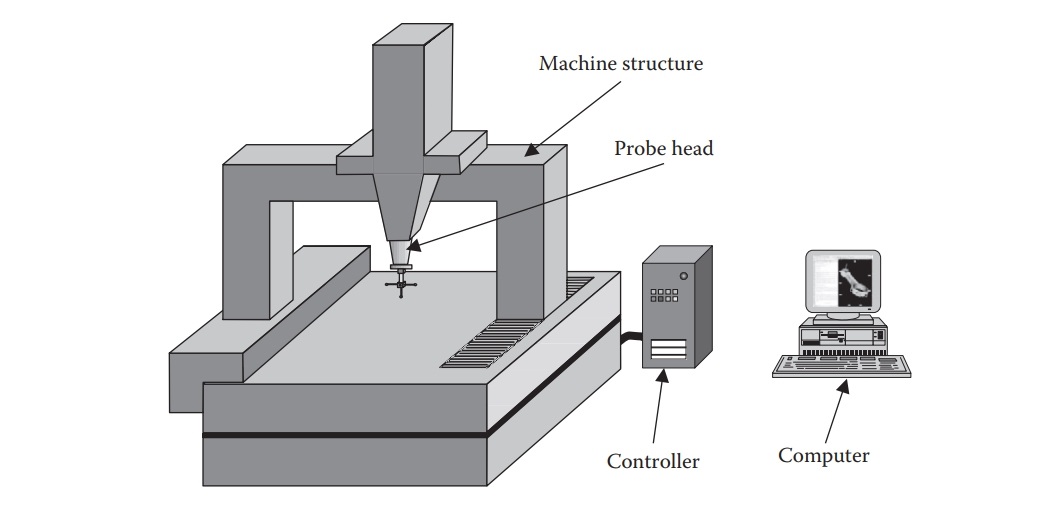

The Coordinate Measuring Machine(CMM) is a measuring device based on a three-dimensional coordinate system. Its basic principle is to obtain the position and shape information of the object in the three-dimensional space by measuring the movement of the probe on the three coordinate axes, so as to realize the precise measurement of the object. and detection. A Coordinate Measuring Machine usually consists of a coordinate measuring system, a measuring probe, a workbench, a computer and related software.

The coordinate measurement system is the core component of a Coordinate Measuring Machine, usually composed of three mutually perpendicular measurement axes and corresponding sensors, used to measure the position of the probe on the three coordinate axes. The measuring probe is the part that is in contact with the object to be measured. It can trigger the measurement action through the trigger, and transmit the measurement result to the computer for processing through the sensor. The workbench is used to place and fix the measured object, and usually has high-precision planes and fixtures to ensure the stability and accuracy of the measurement. The computer and related software are used to control the movement of the measuring instrument, process the measurement data, and generate measurement reports and data analysis.

Coordinate Measuring Machine has many advantages that make it one of the advanced measuring equipment.

CMM is widely used and important in SMC mold production. The following are its main applications in SMC mold production:

To sum up, the Coordinate Measuring Machine has important application value in the production of SMC molds, which can ensure the accurate measurement and quality control of parameters such as the size, shape, position and geometric tolerance of the mold, and help manufacturers improve product quality and reduce reduce production costs and improve production efficiency.

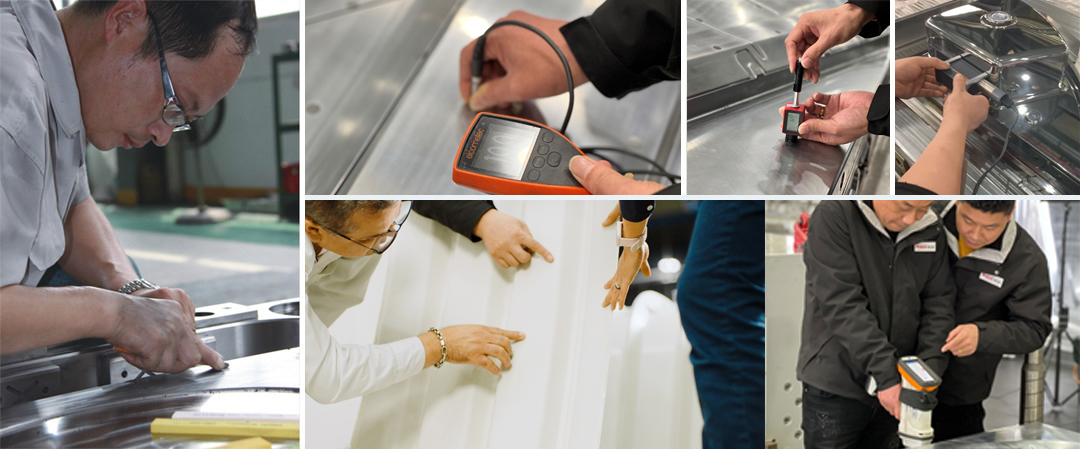

As a professional SMC mould manufacturer, MDC Mould have a lot of equipment and measuring and testing instruments continuous improvement. We have purchased advanced measuring equipment and instruments such as imported Coordinate Measuring Machine, which allow us to understand the quality situation of each product, process, and standard, and provide the best service for our quality control department. Our QC department will conduct product inspection and submit test report within 24 hours after mold test. The report will include comprehensive testing and analysis on product size, appearance, injection technology and physical parameters. We use different inspection standards and tools for different products. In our laboratory, we have carried out different tests on high pressure injection, high speed injection, clamping time, etc. The quality control department proposes modification and improvement suggestions for unqualified products. We have accumulated rich experience and applied it in mold production to provide customers with good solutions.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China