Specialize in Compression molds

Specialize in Compression molds

For any plastic molding technology, molding compound is one of the most important parts. For compression molding, the choice of molding compound has a direct impact on the design and production process of the product and the compression mold. This article briefly introduces the common molding compounds used in compression molding.

Molding compound are mainly composed of the resin matrix, reinforcing materials, fillers, pigments, etc. According to the process and performance requirements, the resin matrix also has various additives such as curing agents, thickeners, internal release agents, solvents, etc. Reinforcing material is the skeleton material of molded plastics, which mainly gives excellent mechanical properties and prevents the expansion of microcracks. The main varieties of reinforcing materials are various glass fiber mats, untwisted roving, untwisted roving cloth, short-cut fibers, ground fibers, glass yarns and fabrics, and other varieties of fibers. The main role of the resin matrix in the molding compound is to bind the reinforcing material and the filler together, which protects the reinforcing material and enables it to be uniformly stressed at the same time under the applied load. Theoretically, most types of thermoplastic and thermosetting resins can be used as resin matrix materials. Among the thermosetting resins, polyester, epoxy, helium-based and phenolic resins are the main ones. Various types of fillers are widely used in molding compounds, mainly to reduce material cost, improve processability, improve certain physical properties, and appearance and assign certain characteristics to molding compounds. Most of the fillers are powder, such as clay, calcium carbonate, talc and some fillers with special performance requirements.

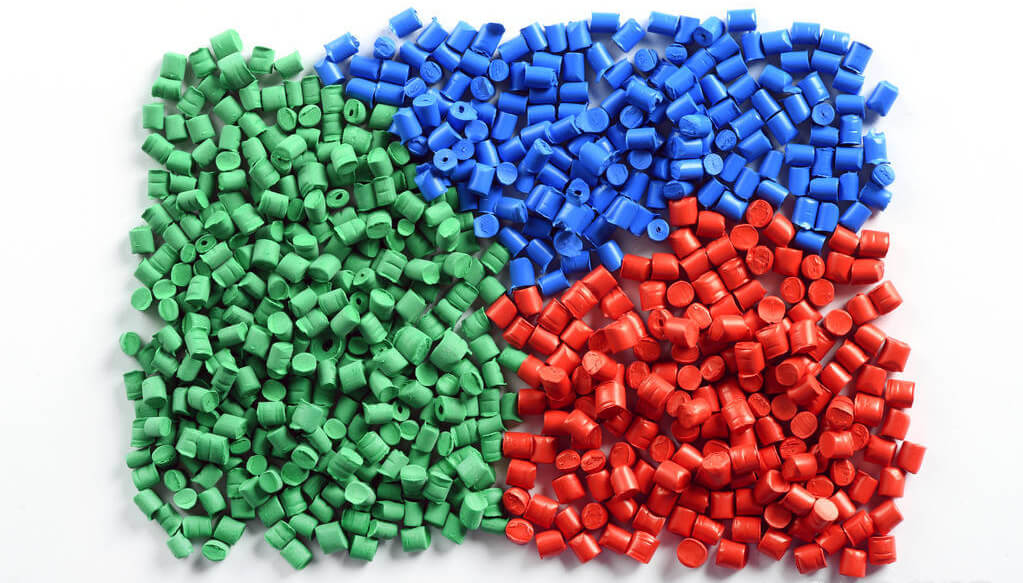

Compared with common plastics, molding plastics have higher geometric stability, are more resistant to extremely high heat and humidity in complex environments, chemical corrosion resistance, high mechanical strength and so on. Molded plastics are used in industries such as aerospace, naval and civilian ships, firearms, electronic and electrical components, and electrical equipment components. Different molding processes require different forms of molding compounds, such as powders, agglomerates, flakes or preforms.

According to different processing methods, molding plastics can be divided into two categories: one is called pre-impregnated material, that is, after the resin impregnated fiber (or fiber and resin mix), after drying and making the resin to a certain degree of pre-curing, such as phenolic resin, epoxy resin, etc.; the other is called thickening material, mainly refers to polyester resin for the base of semi-finished products. The manufacture of such intermediate materials must be added to the resin thickening agent, and the viscosity of the resin impregnated with fiber at the same time change. The resulting semi-finished product is a slightly viscous gel-like material that can be softened and has some fluidity in the second molding step.

| Short-cut Fiber Molding Compounds | Continuous Fiber Molding Compounds | Molded plastic pellets |

| High-strength short fiber molding compound | Tapes | Wood Powder Filled Molding Compounds |

| Prepreg | Pre-preg fabrics | Asbestos powder-filled molded plastics |

| Preformed Blank Molding Compounds | Adhesive yarn tape | Inorganic filler molding compound |

| SMC | Weftless fabric | Organic Filler Molding Compounds |

| BMC | Tape molded plastics | Spherical pellets |

| New Molding Compounds (HMC, UMC) |

Usually, the molding compounds are not put into use immediately after preparation but are usually stored for 3~7 days first. Generally, the molded plastics are sealed in plastic bags and should be protected from light, heat, moisture and other foreign impurities. After a few days of storage, the volatile components in the molded plastics are reduced, and the uniformity and stability of the quality are improved, thus improving the performance of the final molded products to some extent.

The storage period of molding compounds is related to regional climatic conditions and storage conditions. When the molded plastics are stored for a long time, the quality indexes should be re-measured, and if they meet the requirements, they can continue to be used. Suppose the storage time is too long and the quality is not up to standard. In that case, it can be remedied by using solvent to humidify or mixing old and new materials in a certain ratio and changing the molding process appropriately. The storage period of polyester molding compound mainly depends on the type and amount of initiator and polymerization inhibitor used, which is generally more than 3 months at 15 degrees Celsius.

The quality of molding compounds directly affects the performance of molded products. The quality control indexes of molding compounds generally include resin content, volatile matter content and soluble resin content.

We use the highest quality molding compounds, whether we are providing OEM services at MDC Mould or at any stage of production trials for compression mold design. We have a comprehensive sourcing process and two technicians who have been working with composites for many years to ensure the best quality of molding compounds.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China