Specialize in Compression molds

Specialize in Compression molds

Carbon fiber is known for its exceptional strength-to-weight ratio, corrosion resistance, and flexibility. These attributes make it an ideal material for mold making, especially in industries such as automotive, aerospace, and sporting goods. This guide will provide a detailed explanation of how to make a carbon fiber mold, including the materials needed, the steps involved, and the benefits of using carbon fiber for mold making.

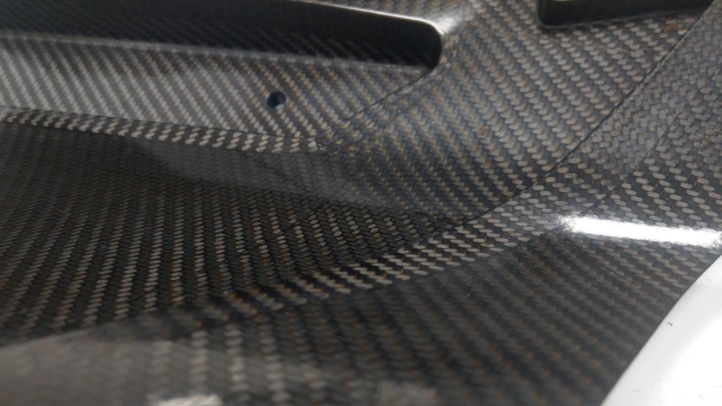

A carbon fiber mold is a durable, lightweight tool used in the production of composite parts. These molds are made from carbon fiber fabric impregnated with resin, forming a strong yet flexible material that can withstand high pressures and environmental stresses. Carbon fiber molds are commonly used in industries where high precision, strength, and durability are critical, such as the production of automotive parts, aerospace components, and sporting equipment.

Creating a carbon fiber mold involves a series of carefully executed steps. Follow this process for an efficient and successful mold making experience:

The first step in making a carbon fiber mold is to prepare the model, which is the object you want to replicate. This pattern can be made from a variety of materials such as clay, plastic, metal, or even a 3D printed model. Make sure the surface is smooth and free of imperfections, as these will be transferred to the finished mold.

Before applying carbon fiber, you will need to apply a release agent to the pattern. This agent will help prevent the carbon fiber from sticking to the pattern and will allow for easy removal of the mold after it cures. Common release agents include wax-based and silicone-based agents.

Begin by cutting the carbon fiber fabric into pieces or strips that fit the pattern. Apply an even coat of epoxy resin to bond the fabric to the surface. Gently press the carbon fiber into the pattern, making sure there are no air bubbles or wrinkles.

After the first layer has cured, continue to apply additional layers of carbon fiber, saturating each layer with resin. The more layers you apply, the stronger the mold will be, but balance strength and weight for optimal results. Allow each layer to cure completely before applying the next.

For added strength and support, apply a backup shell of fiberglass or similar material around the carbon fiber layers. This shell will help maintain the shape of the mold and support its structure during use.

When the mold is fully cured, carefully remove it from the model. You may need to use tools or heat to loosen the mold, but avoid excessive force to prevent cracking.

After removing the mold, trim any excess material and sand the edges to smooth out any imperfections. Use fine sandpaper to achieve a polished surface, ensuring the mold is ready for production.

Carbon fiber molds are widely used in various industries due to their unique properties. The following are some of the most common applications:

Making a carbon fiber mold requires skill, precision, and attention to detail, but the benefits are well worth the effort. The lightweight, strong, and corrosion-resistant properties of carbon fiber make it the material of choice for high-performance molds in industries such as automotive, aerospace, and sporting goods.

By following the steps outlined in this guide, you can successfully create a carbon fiber mold that meets the needs of your specific application. Whether you are producing prototypes, high-volume production parts, or custom designs, carbon fiber molds provide the durability and precision needed for exceptional results.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China