Specialize in Compression molds

Specialize in Compression molds

In the realm of material manufacturing and molding, hot press molding and compression molding are two widely utilized techniques. While they share similarities, their unique characteristics make them suitable for different applications. It's important for manufacturers to understand these differences so they can choose the best process for their needs.

Hot press molding, often referred to as hot compression molding, involves applying heat and pressure simultaneously to shape and cure materials. This process is often used to make composite materials, like carbon fiber reinforced plastics (CFRP), sheet molding compound (SMC), and bulk molding compound (BMC).

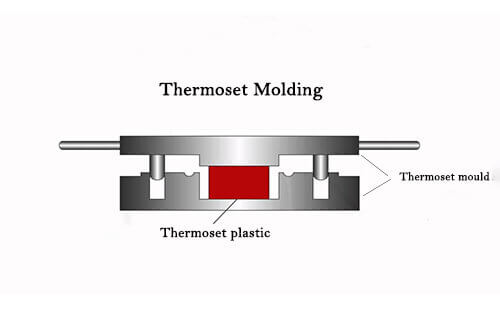

Compression molding is a widely used process where a material, typically a pre-measured amount of thermosetting polymer, is placed into a heated mold cavity. The mold is then closed, and pressure is applied to shape the material as it cures.

| Feature | Hot Press Molding | Compression Molding |

|---|---|---|

| Heat Application | Integral to the process; molds are heated | Optional; molds can be heated or room temperature |

| Pressure Application | Higher pressure required | Moderate pressure sufficient |

| Material Compatibility | Primarily thermosetting materials | Both thermosetting and thermoplastic materials |

| Precision | High dimensional accuracy | Moderate to high precision, depending on material |

| Cycle Time | Longer, due to curing requirements | Shorter, especially with thermoplastics |

| Applications | Advanced composites and structural components | Everyday plastic and composite parts |

When selecting between hot press molding and compression molding, manufacturers must consider the following factors:

Hot press and compression molding are used in many industries:

Hot press molding and compression molding are both very important in modern manufacturing. Hot press molding is great at making strong, precise parts. Compression molding is good for making a lot of different things, and it's cheap. By understanding the differences between these methods and knowing when to use them, manufacturers can make better products.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China