Specialize in Compression molds

Specialize in Compression molds

Discover the key factors that influence compression molding cycle time and how to optimize production efficiency.

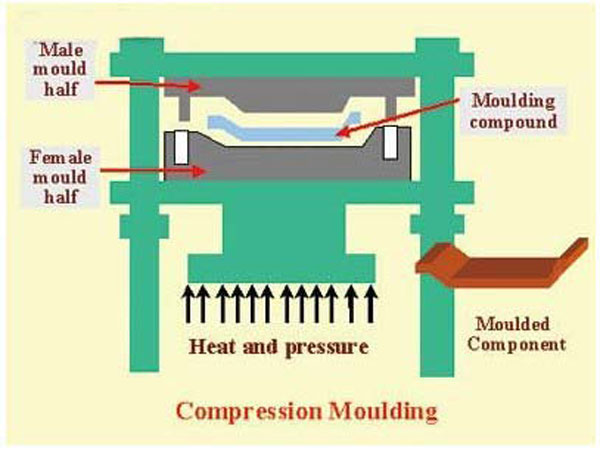

Compression molding consists of multiple stages, each impacting the total processing time. From material preheating to curing and cooling, every step plays a crucial role.

Several factors influence the cycle time of compression molding:

Different materials require varying processing times:

Thicker and more complex parts require longer curing times. A 3 mm thick part may cure in 2 minutes, while a 10 mm thick part may take 7 minutes.

Higher mold temperatures and pressure settings reduce cycle time by ensuring efficient material flow and faster curing.

| Industry | Material | Cycle Time |

|---|---|---|

| Automotive | SMC, BMC | 1-5 minutes |

| Aerospace | Carbon Fiber Composites | 10-20 minutes |

| Electrical | BMC, Phenolic Resins | 1-3 minutes |

| Consumer Goods | Rubber, Thermoplastics | 3-10 minutes |

Compression molding cycle time depends on material type, part complexity, curing requirements, and process optimization. By selecting the right materials, optimizing mold conditions, and incorporating automation, manufacturers can enhance efficiency and reduce costs.

For high-quality compression molded parts, understanding these key factors is essential to achieving faster production cycles.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China