Fundamentals of Carbon Fiber and Glass Fiber (FRP)

Join Date: 2024-12-14

Take a look at the ins and outs of carbon fiber and fiberglass (FRP), including the different types, properties, production processes, and how they're used in various industries.

What exactly is carbon fiber?

Carbon fiber is a lightweight, high-strength material made mostly of carbon atoms. It's made through a process called carbonization, where a precursor fiber is heated to high temperatures (up to 1300°C) in an inert environment, transforming it into carbon fiber with a crystalline structure.

What makes carbon fiber so special?

-

Its high strength, for starters. Carbon fiber is much stronger than steel, making it ideal for applications that require high strength.

-

It's lightweight, too. It's a lot lighter than metal, which makes it perfect for applications where weight is a factor.

-

Corrosion Resistance: Unlike metals, carbon fiber doesn't corrode, so it's great for harsh environments.

-

It also has high thermal conductivity. Carbon fiber can handle extreme temperatures, making it perfect for aerospace, automotive, and industrial applications.

What is CFRP (carbon fiber reinforced plastic)?

CFRP stands for carbon fiber reinforced plastic. It's a composite material made by embedding carbon fibers into a polymer matrix, like epoxy or polyester resin. This combination of materials makes the composite stronger and lighter.

CFRP has some great benefits

-

It's lightweight but still super strong. CFRP brings together the lightness of plastic with the strength of carbon fiber, making it perfect for industries like aerospace and automotive.

-

Design Flexibility: CFRP can be molded into pretty much any shape you can think of, so you can get highly custom designs.

-

Durability: CFRP can stand up to wear and tear, fatigue, and environmental stress.

Carbon Fiber Terminology 101

Knowing the lingo used in carbon fiber manufacturing and design is key to choosing the right material for the job. Here are some key terms you should know:

What is "tow"? What do the numbers 1K, 3K, and 24K mean?

A tow is just a bundle of carbon fibers. The number (like 1K, 3K) shows how many filaments are in the tow.

-

1K Tow: It contains 1,000 carbon fibers.

-

3K Tow: A 3K tow is made up of 3,000 carbon fibers. It contains 3,000 carbon fibers.

-

24K Tow: It's got 24,000 carbon fibers in it.

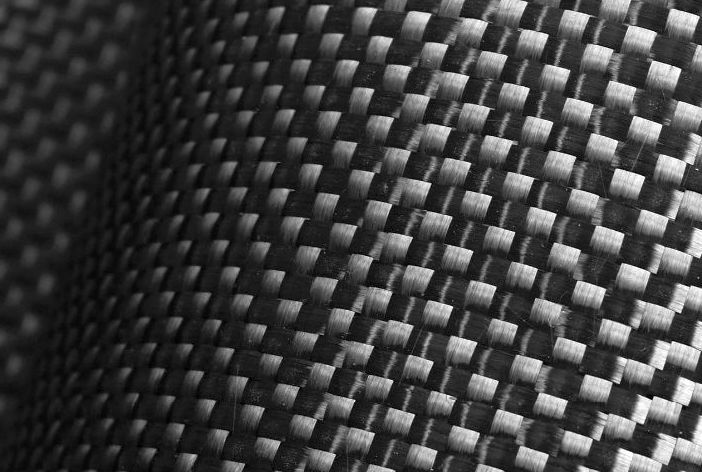

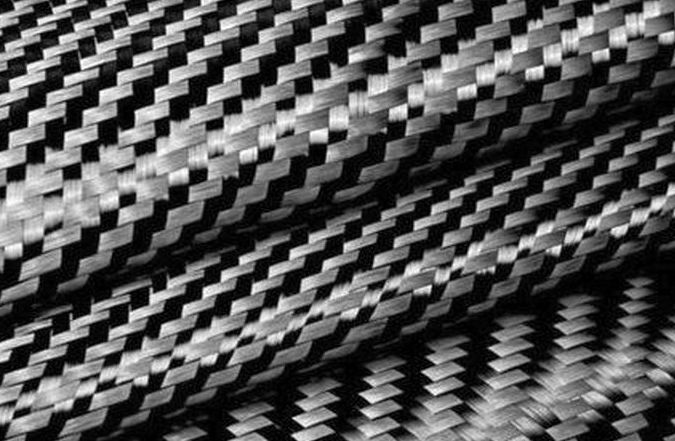

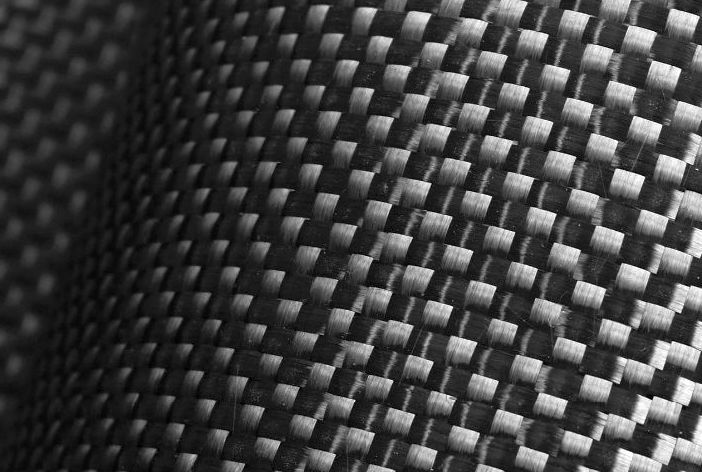

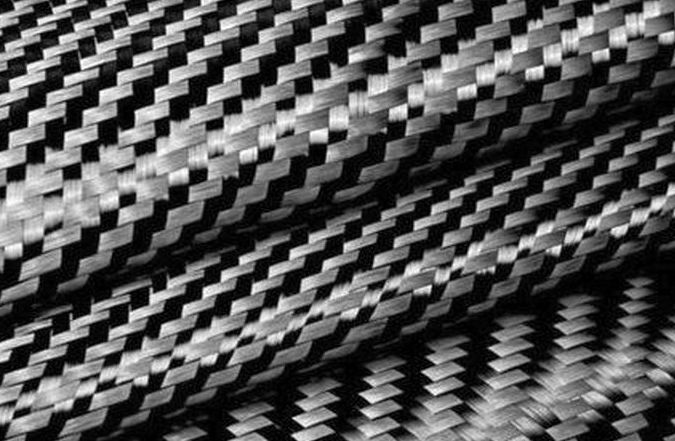

What exactly is carbon fiber fabric?

Carbon fiber fabric is made by weaving carbon fiber filaments into textiles like plain or twill weaves. The weave pattern affects the material's properties. Plain weave is simple and strong, while twill weave is better for complex shapes because it offers more flexibility.

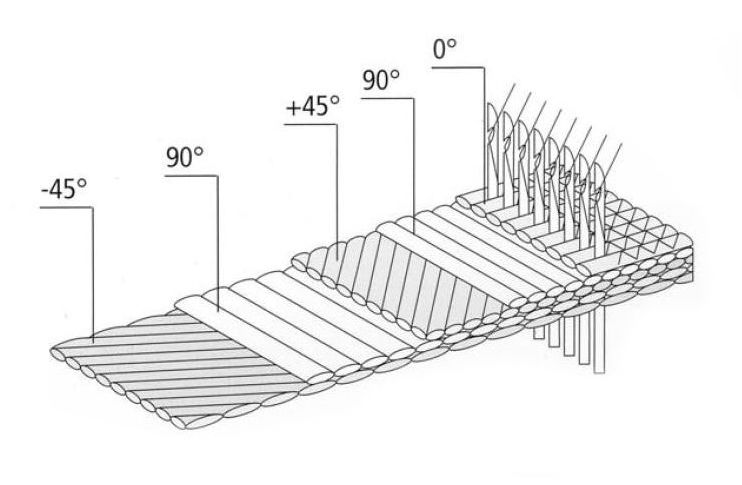

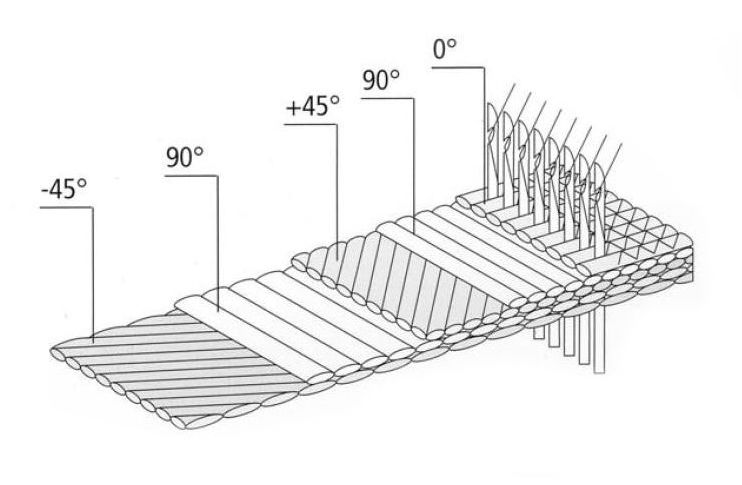

What is unidirectional (UD) carbon fiber?

Unidirectional (UD) is a material where the fibers are aligned in one direction. This makes it really strong in that direction, which is why it's often used in aerospace and automotive applications. There are other variations too, such as:

-

Bidirectional: The fibers are arranged at 0° and 90° to give you balanced strength.

-

Triaxial: The fibers are arranged at 0°, +45°, and -45°, which gives them great multidirectional strength.

-

Quadraxial: The fibers are arranged at 0°, 90°, +45°, and -45° to give you the maximum multidirectional strength.

What exactly is high modulus carbon fiber?

High modulus carbon fiber is a type of carbon fiber that's known for being really stiff but not so flexible. It's usually grouped into a few different categories based on how rigid it is and how strong it is when pulled:

-

HT (High-Tensile): High strength and performance.

-

IM (Intermediate Modulus) is stiffer than regular carbon fiber.

-

HM (High-Modulus): It's super stiff, making it perfect for aerospace applications.

-

UHM (Ultra High-Modulus): It's used in specialized applications that require the highest stiffness.

Where You'll Find Carbon Fiber and CFRP

Carbon fiber and CFRP are used in a lot of different industries because they're strong, lightweight, and durable. Some common applications include:

-

Aerospace: Carbon fiber is used in structural components for aircraft, spacecraft, and satellites.

-

Automotive: It's used in body panels, frames, and interior parts to reduce weight and enhance efficiency.

-

Sports equipment: Bicycles, tennis rackets, and golf clubs are made from carbon fiber for enhanced performance.

-

Medical devices: Bicycles, tennis rackets, and golf clubs are made from carbon fiber for enhanced performance.

-

Marine: Carbon fiber is used in boat hulls and marine components for strength and corrosion resistance.