Specialize in Compression molds

Specialize in Compression molds

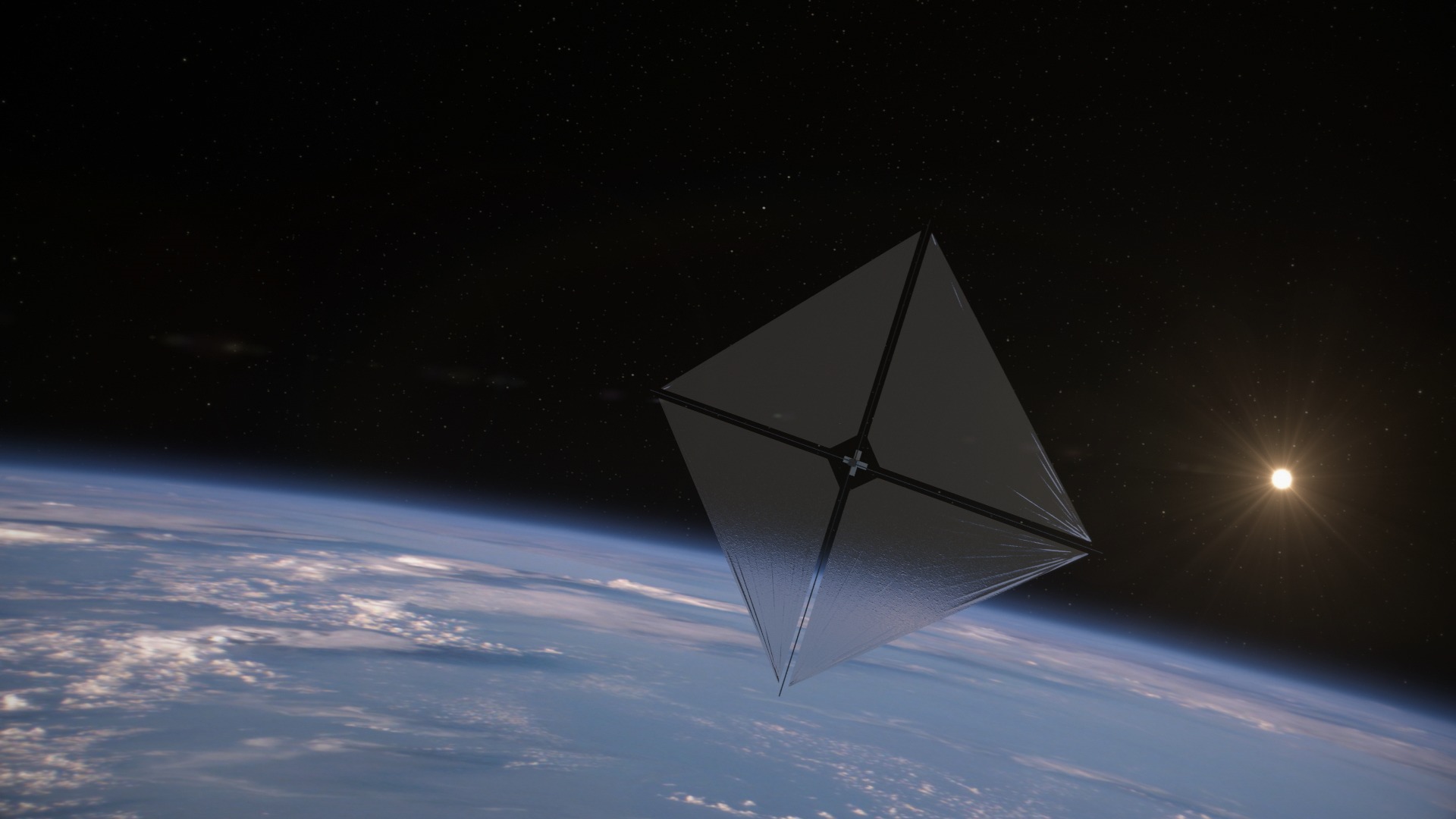

As advancements in space exploration continue to reach new heights, innovations in manufacturing materials and processes have become critical. A recent example of this is NASA's successful deployment of its Advanced Composite Solar Sail System (ACS3), which utilizes solar sails made from advanced composite materials, including carbon fiber molds. This technology showcases the potential of materials like carbon fiber and composite molds in aerospace applications, highlighting their ability to enable sustainable, fuel-free propulsion systems.

Carbon fiber molds are instrumental in creating lightweight and high-strength parts, especially in aerospace where every gram of weight matters. Carbon fiber composites are made by weaving carbon fibers into a fabric, which is then combined with a resin and cured in a mold to form solid structures. These molds are crucial for producing components like solar sails, as demonstrated by the ACS3 mission.

Beyond aerospace, carbon fiber molding is widely used in the automotive, sports, and high-performance industrial sectors where weight and strength are critical factors. The lightweight nature of carbon fiber molds also contributes to reducing costs in space missions.

Composite molds combine materials such as carbon, glass, and aramid fibers embedded in a resin matrix, resulting in versatile molds capable of withstanding high temperatures and pressures. These molds provide significant advantages in aerospace, as they enable the manufacturing of large, complex structures with precision.

The ACS3 solar sail system is a testament to the power of composite materials in space. Composite molding allows for the construction of durable, lightweight components that can be maneuvered and controlled in space, maximizing the effectiveness of solar sails. Other industries, such as renewable energy and automotive, also benefit greatly from composite molding processes.

Compression molds are widely used in high-volume manufacturing processes. The compression molding process involves placing preheated materials into a mold, where they are shaped under pressure. This method allows for the rapid production of identical parts with high precision, making it ideal for industries like aerospace, where strength and durability are essential.

In space exploration, compression molding is key to producing essential components like structural panels and engine covers. This process also reduces material waste and allows for the production of parts that can endure the harsh environments of space.

The successful ACS3 mission illustrates the growing importance of carbon fiber molds, composite molds, and compression molds in space exploration. These technologies not only push the boundaries of aerospace but also offer innovations that will impact a variety of industries. As engineers continue to refine these processes, the use of advanced molding techniques will become even more widespread.

Industries aiming to reduce weight, improve efficiency, and lower production costs will increasingly turn to carbon fiber molding and composite molding techniques. The durability and versatility of these materials make them ideal for applications ranging from space technologies to automotive and industrial manufacturing.

The advancement of space technologies like NASA’s ACS3 system highlights the critical role of carbon fiber molds, composite molds, and compression molds. These innovative materials and molding techniques enable the creation of lightweight, durable, and efficient components that are shaping the future of space exploration and manufacturing industries. By adopting these advanced processes, industries can develop cost-effective solutions for their most challenging applications.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China