Specialize in Compression molds

Specialize in Compression molds

Carbon fiber layup is a crucial process in composite material manufacturing, widely used in aerospace, automotive, sports equipment, and industrial applications. This article explores various layup techniques, key considerations, and the benefits of using carbon fiber composites.

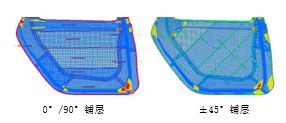

The carbon fiber layup process involves arranging carbon fiber fabrics or preforms in a mold and impregnating them with resin to create high-strength, lightweight composite structures. The process ensures optimal fiber alignment and resin distribution, enhancing mechanical performance.

The hand layup technique is a manual process where carbon fiber sheets are positioned in a mold and impregnated with resin. It is cost-effective and widely used for prototyping and low-volume production.

Vacuum bagging enhances the hand layup process by applying a vacuum to remove excess resin and air bubbles, improving the composite’s strength and reducing void content.

Prepreg layup involves using pre-impregnated carbon fiber sheets that contain an exact resin-to-fiber ratio. These sheets require controlled curing conditions, usually in an autoclave, to achieve superior mechanical properties.

Also known as Vacuum Assisted Resin Transfer Molding (VARTM), this process draws resin through dry carbon fiber layers using vacuum pressure, ensuring complete wet-out and reducing excess resin.

Carbon fiber composites are widely used in aircraft fuselage panels, wings, and interior structures due to their exceptional strength-to-weight ratio.

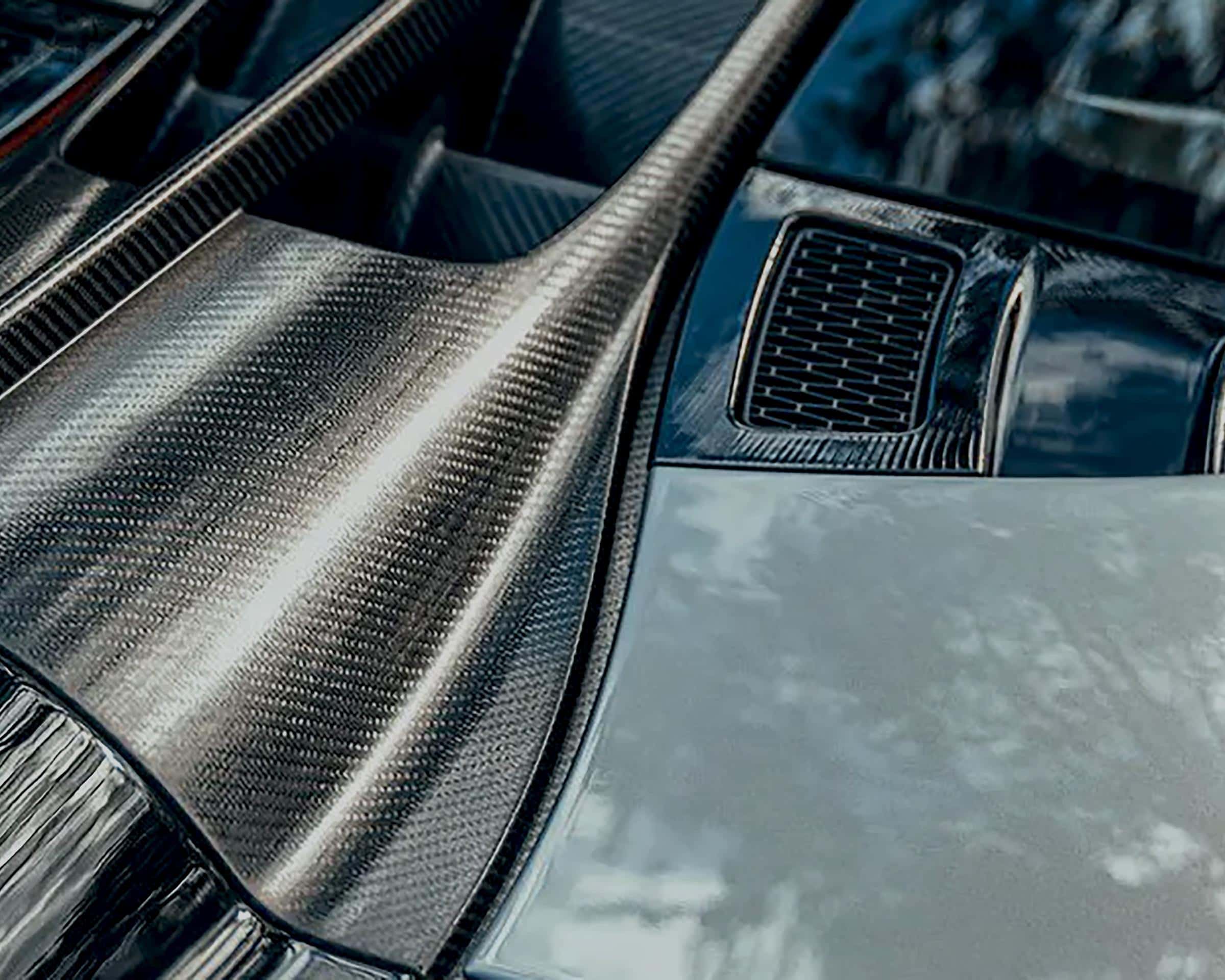

High-performance vehicles use carbon fiber components like hoods, spoilers, and chassis parts to enhance aerodynamics and reduce weight.

Bicycles, tennis rackets, golf clubs, and racing helmets benefit from carbon fiber’s durability and lightweight properties.

Carbon fiber is used in robotic arms, prosthetics, and wind turbine blades for its high stiffness and corrosion resistance.

The carbon fiber layup process is a cornerstone of composite material fabrication, offering unmatched performance benefits across industries. As advancements in automation, materials, and processing techniques continue, carbon fiber composites will play an even more significant role in lightweight and high-performance engineering solutions.

Contact US

Email: master@zjmdc.com

Tel: +86 576 84616076

Fax: +86 576 84616079

Mobile: +86 13906573507(Mr. Wang)

Address: No.116 mochuang road, Huangyan Xinqian street,Taizhou,Zhejiang,China